Would you like to visit an Oracle country site closer to you?

Souhaitez-vous visiter le site d’un pays Oracle plus proche ?

See this page for a different country/regionPrésentation d'Oracle Fusion Cloud Supply Chain Planning

Obtenez de meilleurs résultats plus rapidement avec une planification de bout en bout dans le cloud.

Planifiez l'avenir de la prise de décision dans votre supply chain

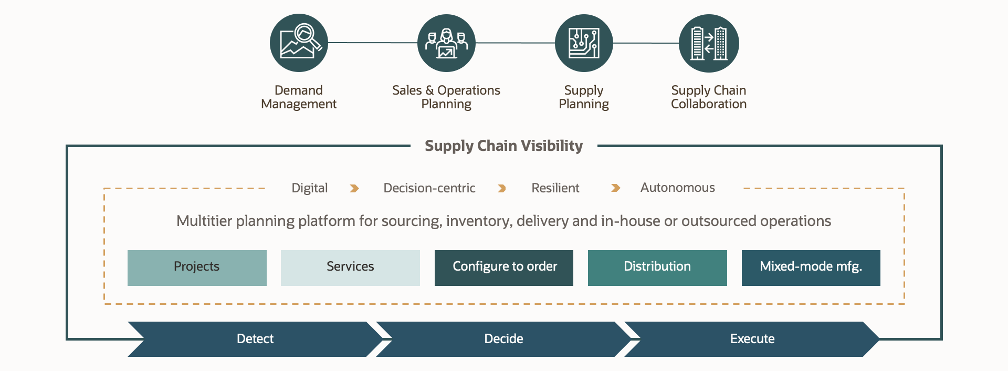

Les supply chains d'aujourd'hui sont plus mondiales, complexes et volatiles que jamais. Pour augmenter les revenus et réduire les coûts, vous avez besoin d'une planification de la supply chain prête pour l'avenir, rapide, simple et intelligente. Oracle Supply Chain Planning vous offre de meilleurs moyens d'anticiper la demande, de gérer l'approvisionnement et d'aligner les actions des parties prenantes et des partenaires commerciaux sur vos objectifs.

Créez vos plans stratégiques

Les entreprises performantes élaborent des plans d’activité intégrés pour aligner la stratégie financière et opérationnelle. Oracle Sales and Operations Planning convertit les objectifs de chiffre d'affaires, de marge et de coût des DAF en plans de supply chain globaux correspondants. Grâce à sa capacité de planification globale, vous pouvez identifier les opportunités d'évolution de la gamme de produits, de l'approvisionnement, de la production et des stratégies de distribution pour atteindre les objectifs de rentabilité et de croissance.

Collaborez pour créer de la cohésion

Les principales parties prenantes doivent contribuer, collaborer et parvenir à un consensus sur la planification produit, finance, commerciale, marketing, supply chain et RH connectée et ambitieuse. Les étapes et les workflows de planification basés sur les bonnes pratiques guident les utilisateurs à travers les tâches, le suivi des jalons et la progression globale.

Intégrez la planification de vos activités, de vos stratégies et de vos opérations

Oracle Supply Chain Planning fait le lien entre les plans stratégiques et l'exécution des ventes et des opérations (S&OE). Vous pouvez déployer des prévisions de consensus de planification d'entreprise intégrée (IBP) comme référence pour des prévisions tactiques plus détaillées dans Oracle Demand Management, ainsi que des plans d'approvisionnement tactiques dans Oracle Supply Planning.

Mesurez, anticipez et modelez la demande

Oracle Demand Management peut combiner la demande, telle que les commandes et les expéditions, avec des signaux météorologiques, économiques, sociaux et autres signaux de données externes afin d'améliorer la détection de la demande. Il décompose également la demande en composants de base, de tendance, saisonniers et basés sur les événements afin que vous puissiez comprendre ce qui motive la prévision.

Tirez parti du machine learning intégré pour améliorer la précision des prévisions

Oracle Demand Management utilise le mélange bayésien, l'optimisation des dégradés eXtreme et d'autres techniques de machine learning pour prévoir la demande plus précisément. Il s'adapte pour gérer les articles à cycle de vie court, intermittents, saisonniers, promotionnels et configurés. Il détecte également automatiquement les valeurs aberrantes, comble les écarts de données et règle les paramètres ciblés pour minimiser les erreurs de prévision.

Obtenez des analyses grâce à un conseiller en planification intelligent

Prenez des décisions de planification en toute confiance. Un conseiller en planification intégré présente aux utilisateurs une analyse continue de la demande de nouveaux articles, des perturbations de l'approvisionnement, des écarts de délai, des paramètres obsolètes et d'autres problèmes. Il fournit également des recommandations d'action écrites en texte simple.

Obtenez des analyses grâce à un conseiller en planification intelligent

Vous pouvez filtrer et hiérarchiser les alertes et les prévisions intelligentes du conseiller en planification, vérifier la précision prévue des recommandations et créer un lien vers la vue de planification appropriée en contexte pour prendre des mesures.

Automatisez le réapprovisionnement en fonction de la demande

Oracle Demand Management peut automatiser les processus de réapprovisionnement par phase et en fonction de la demande sur un réseau multiniveau de magasins, de dépôts ou d'autres sites stockés régulièrement. Il peut également gérer les emplacements de réapprovisionnement automatique périodique (PAR) dans les environnements cliniques. Résolvez rapidement les ruptures de stock et autres exceptions de stock grâce à des simulations graphiques interactives. Vous pouvez également consolider les achats pour obtenir des conditions de remise et réduire les coûts logistiques.

Planifiez votre approvisionnement pour maximiser le service au moindre risque et au moindre coût

Oracle Supply Planning peut déterminer le stock, la capacité et l'approvisionnement en matériaux requis pour répondre à la demande, y compris les livraisons directes, les bons de commande adossés et les articles fabriqués par contrat. Il met également en évidence les exceptions telles que la compression de la demande, les pénuries de matériaux et les surcharges de ressources qui peuvent mettre la demande en danger. Au fur et à mesure que vous choisissez parmi les actions d'expédition proposées, les augmentations de capacité ou d'autres interventions, vous pouvez voir leur impact financier et de service client potentiel.

Contournez les contraintes de matériaux, de ressources et de capacité

Oracle Supply Planning utilise la planification hybride basée sur les contraintes pour évaluer automatiquement les moyens de prévenir les violations de contraintes, en formulant des recommandations pour garantir que les demandes sont satisfaites à temps. La solution évalue les ressources de remplacement, les substituts, les fournisseurs de remplacement et la construction à l'avance comme des moyens de surmonter les contraintes matérielles et de capacité. Vous pouvez définir des contraintes de capacité inviolables pour certaines ressources et certains fournisseurs, tout en permettant à d'autres d'être surchargés si nécessaire.

Adaptez votre planification aux besoins de votre marché

Les processus et les objectifs de planification diffèrent considérablement selon le secteur. Que vous mettiez l'accent sur la distribution en gros, la fabrication en mode mixte, l'ingénierie à la commande, les supply chains basées sur les projets ou cliniques, Oracle Supply Chain Planning s'adapte à vos besoins. La planification basée sur les attributs fait correspondre la demande et l'approvisionnement en fonction du grade minimum, du pays d'origine, du projet et d'autres critères flexibles.

Planifiez et surveillez vos activités de production

Oracle Supply Planning planifie la production au cours de la journée afin d'optimiser l'utilisation des goulets d'étranglement, d'augmenter le débit en usine et d'améliorer les performances de livraison. Il ajuste de manière proactive le séquencement et le calendrier des travaux dans les usines en fonction des événements en temps réel sur l'atelier afin de réduire les changements, les stocks, les déchets et les accélérations.

Gérez stratégiquement votre carnet de commandes

Les fonctions de gestion du carnet de commandes d'Oracle Supply Planning vous aident à hiérarchiser et à replanifier vos commandes client ouvertes lorsque les articles sont prêts à être affectés ou que la disponibilité de l'approvisionnement change. Simulez d'autres scénarios et modifiez l'approvisionnement, accélérez le transport ou fractionnez les lignes pour réduire les retards de livraison, augmenter les ventes ou préserver les marges.

Engagez vos partenaires commerciaux à réduire les perturbations de la supply chain

Dans les supply chains mondiales d'aujourd'hui, il est essentiel de synchroniser vos plans avec les clients, les fabricants en sous-traitance et les fournisseurs. Oracle Supply Chain Collaboration offre une visibilité sur la demande en aval et sur les engagements en matière d'approvisionnement en amont, ce qui vous alerte en cas de non-concordance. Avec un avertissement préalable, vous pouvez collaborer sur plusieurs niveaux de la supply chain pour assurer un alignement de bout en bout.

Activez un centre de contrôle de la supply chain pour votre entreprise

Oracle Supply Chain Planning est un composant essentiel de la solution Supply Chain Command Center d'Oracle. Les informations de planification et les modèles de machine learning pilotent les actions de fabrication, de stock, de transport et d'achats. Des cas d'utilisation prédéfinis peuvent détecter, décider et exécuter des réponses aux problèmes sur l'ensemble de votre réseau de supply chain.