This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date |

What's Changed |

Notes |

|---|---|---|

| 14 JUN 2018 |

Created initial document. |

This guide outlines the information you need to know about the first release of Oracle Adaptive Intelligent Applications for Manufacturing (Release 18.2) and describes any tasks you might need to perform for the update. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

We would like to remind you if your system has modified security structures you may need to advise your security administrator of new features you would like to take advantage of. To assist you Appendix A provides a listing of the new features and the security attributes needed to employ the new features when you have decided to implement them.

We welcome your comments and suggestions to improve the content. Please send us your feedback at AIMFGCS_help_ww_grp@oracle.com.

We continue to add many new features to Oracle Cloud Applications and we now give you the option to take advantage of new functionality at a pace that suits you. The ‘New Features UI’ is available to you from your cloud homepage, where you can make your choices and do any configuration necessary. The table below offers a quick view of the actions required to enable each of the new features.

| Action Required to Enable Feature |

||||

|---|---|---|---|---|

| Feature |

Automatically Available |

End User Action Required |

Administrator Action Required |

Oracle Service Request Required |

| Acquiring and Storing Data |

||||

| |

||||

| |

||||

| Preparing Data |

||||

| |

||||

| |

||||

| Analyzing Data |

||||

| |

||||

| |

||||

| |

||||

| |

||||

| |

||||

| Presenting Data |

||||

| |

||||

| |

||||

| Managing Security and Access Control |

||||

| |

||||

| |

||||

| Background Processes |

||||

| |

||||

Oracle Adaptive Intelligent Applications for Manufacturing

Oracle Adaptive Intelligent Applications for Manufacturing is a unique SaaS (subscription based) offering on the Oracle Public Cloud that collects, stores, and analyzes massive amounts of Operational Technology (OT) data coming from shop floor systems such as Equipment, Machines, Sensors, Test Stations etc. and contextualizes it with Information Technology (IT) data coming from business applications such as SCM, ERP, HCM, CRM, MES, Quality and analyzes it by applying machine learning, data mining, and artificial intelligence techniques to discover key patterns and correlations that affect manufacturing efficiencies and provides actionable predictive analytics to maximize yield, and minimize defects, scrap, cycle times, costs etc. It also provides comprehensive capabilities for backward and forward tracing of products and processes within manufacturing and supply chain spanning manpower, machine, material, method and management aspects to facilitate rapid root cause, impact and containment analysis.

Initial release of Adaptive Intelligent Applications for Manufacturing Cloud Service consists of following components:

Oracle Adaptive Intelligent Applications for Manufacturing provides a number of CSV templates to ingest historical manufacturing operations data from a wide variety and heterogeneous mix of Information Technology (IT) systems spanning ERP, MES, Quality/LIMS and Operational Technology (OT) systems that include equipment, machines, and other sensor enabled shop floor devices and environmental data.

The application provides a robust and comprehensive data lake to store data from ERP/SCM/CRM/HCM/MES/Quality systems in Relational/Structured data store, to store data from various machines and sensors such as temperature, pressure etc. in Time Series data store and to store notes, comments and log files in Unstructured data stores.

Using Sensor Devices UI, user can register the sensor devices and map the devices to equipment instances defined in the ERP system. User can search and manage sensor device definition and mapping between sensor device and equipment instance.

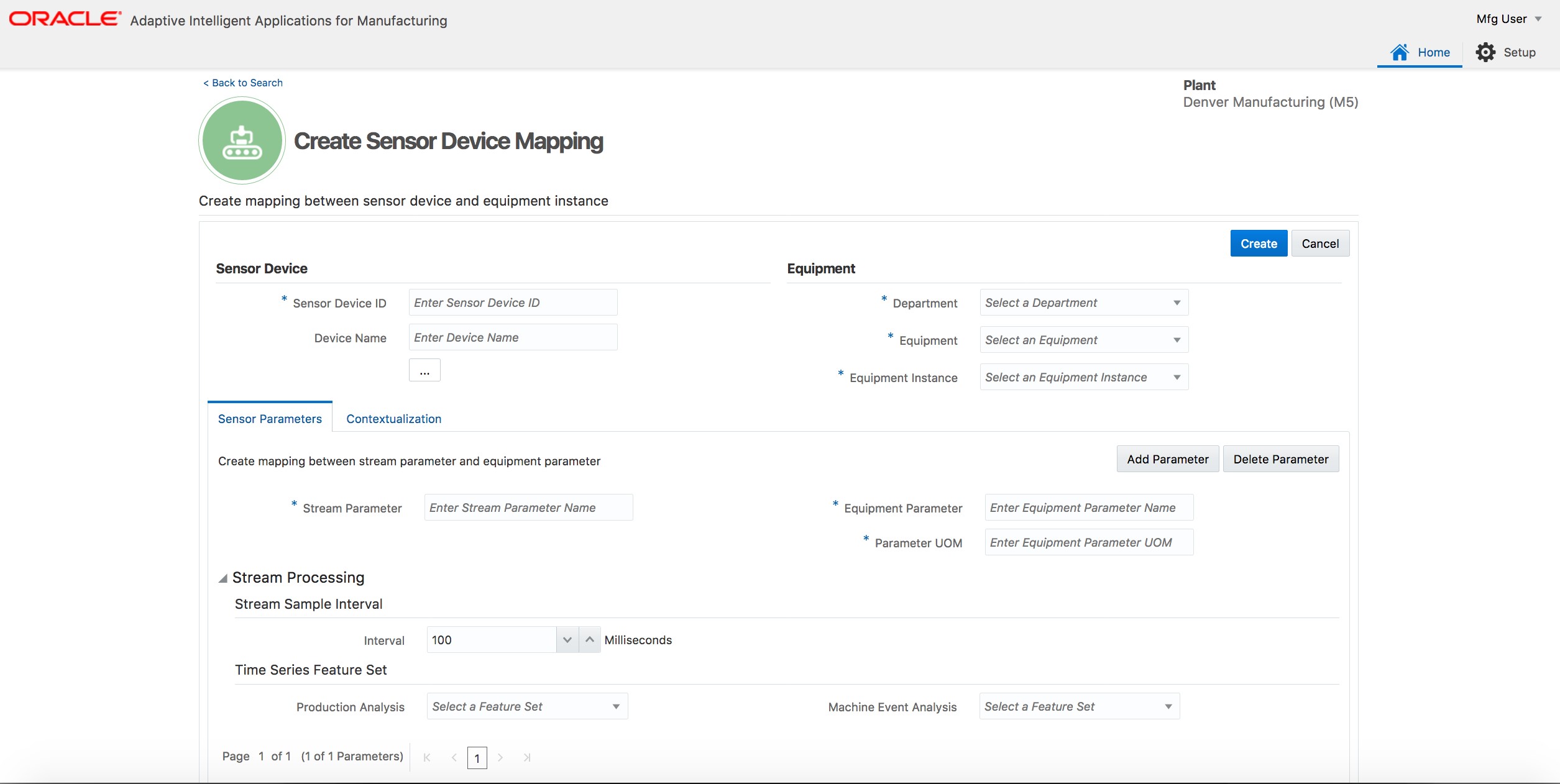

Create Sensor Device Mapping Screen

Create Sensor Device Mapping UI provides the Device and Equipment related fields to register the sensor devices and map to an equipment.

- Sensor Parameters tab provides the fields to map the stream parameter to the equipment process parameter.

- Contextualization tab provides the methods to be prioritized for the Equipment Contextualization and Work Order contextualization.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator role to be able to access the UI.

Tips and Considerations

There can not be more than one sensor device that can be mapped to a given process parameter of the equipment instance.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Acquiring Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Upload and Contextualize Sensor Data

User can manage batch processing of time series data generated from shop floor machines by uploading the data in csv file format and store the data in Oracle Storage Cloud Service. The uploaded data gets contextualized with the resource and work order information.

Upload File Screen

Using Upload File UI, user can upload the files with the csv or csv.gz format. User can download the template to review instructions and the sample data before uploading the csv format file. User can either uploaded the sensor stream data or the event/alert data.

- User can search or manage the files for the quicker access to the relevant files.

- If the records error due to contextualization issues, it provides the file with error records and error reason. You can correct the records, upload the file and contextualize the data.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator role to be able to access the UI.

Tips and Considerations

There can be only one file included in the csv.gz format and can not exceed the size 5GB.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Acquiring Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Oracle Adaptive Intelligent Applications for Manufacturing provides robust capabilities to prepare the data for analysis by extracting the features from time series data and features from structured data.

- The Time Series data in the context of a machine and work order can be sliced into multiple time segments and summarized using various functions such as Average, Standard Deviation, Min, Max etc.

- The solution provides a unique capability to convert the time series data into SAX(Symbolic Aggregate approXimation) format and apply summarization functions such as SAX Pattern count which can be used for the analysis.

- The solution provides out-of-box features extracted from the structured entities of the data lake such as operation duration, resource usage, operator worked etc applicable under Man, Machine, Material, Method and Management categories.

- The solution provides configuration of custom specific features using web services which can be used for the analysis.

Setup Time Series Feature Sets

Using Time Series Feature Sets UI, user can configure the segments required to slice the time series data and configure the summary functions that can be used in the data mining analysis as features.

Create Time Series Feature Sets Screen

Create Time Series Feature Sets UI provides the various time segments and summarization functions to create features out of the time series data.

- Fixed, Sliding and Full time segment options are available to slice the data.

- Simple functions such as Average, Min, Max, Standard Deviation etc and Advanced functions such as SAX Bitmap and SAX Pattern Count are available to create feature sets.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator role to be able to access the UI.

Tips and Considerations

According to the requirement of analysis of data, user has to carefully choose the time segments and functions in creating the time series feature sets and assign to applicable process parameters (like Temperature, Pressure etc) defined in the sensor device mapping screen.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Preparing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Create Data Preparation Request

Data analyst or data scientist can submit a request to extract the seeded meta data of features for a defined context from structured data from transactional applications for manufacturing operations, semi-structured data like equipment time series data and custom predictors from other systems like LIMS, MES etc.

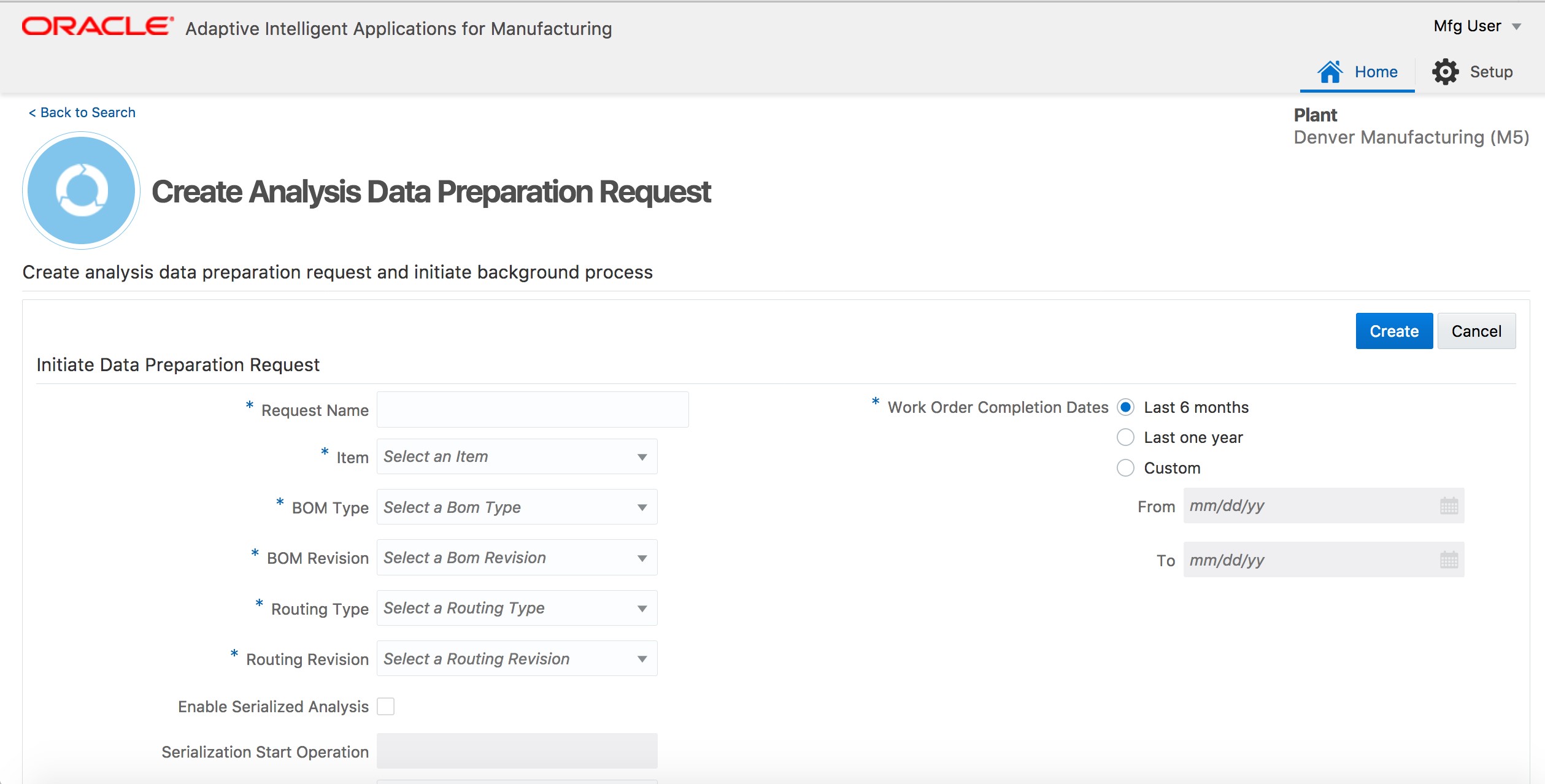

Create Analysis Data Preparation Request Screen

Create Analysis Data Preparation Request Screen provides the following fields to define the context.

- For discrete manufacturing – item, BOM type, routing type, operation, work orders range.

- For process manufacturing – item, recipe, operation, work orders range.

- For discrete serialized manufacturing – item, BOM type, routing type, operation, enable serial analysis, serialization start operation, work orders range.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

The meta data or features extracted belongs to the the operation of the data prep context and all the previous operations as per the routing. The data preparation request has to be created with an operation of focus of analysis.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Preparing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

After the successful creation of data prep request, data analyst or data scientist can analyze the results of sensor summary for a given data preparation request. Sensor Summary Results UI provides user to view the details about the time series features created for all the process parameters of resources having the time series feature set assigned. The Time series features are generated during the process of creating analysis data preparation request. User can drill into a specific parameter to understand and compare the summary function values of features across the work orders in the data set.

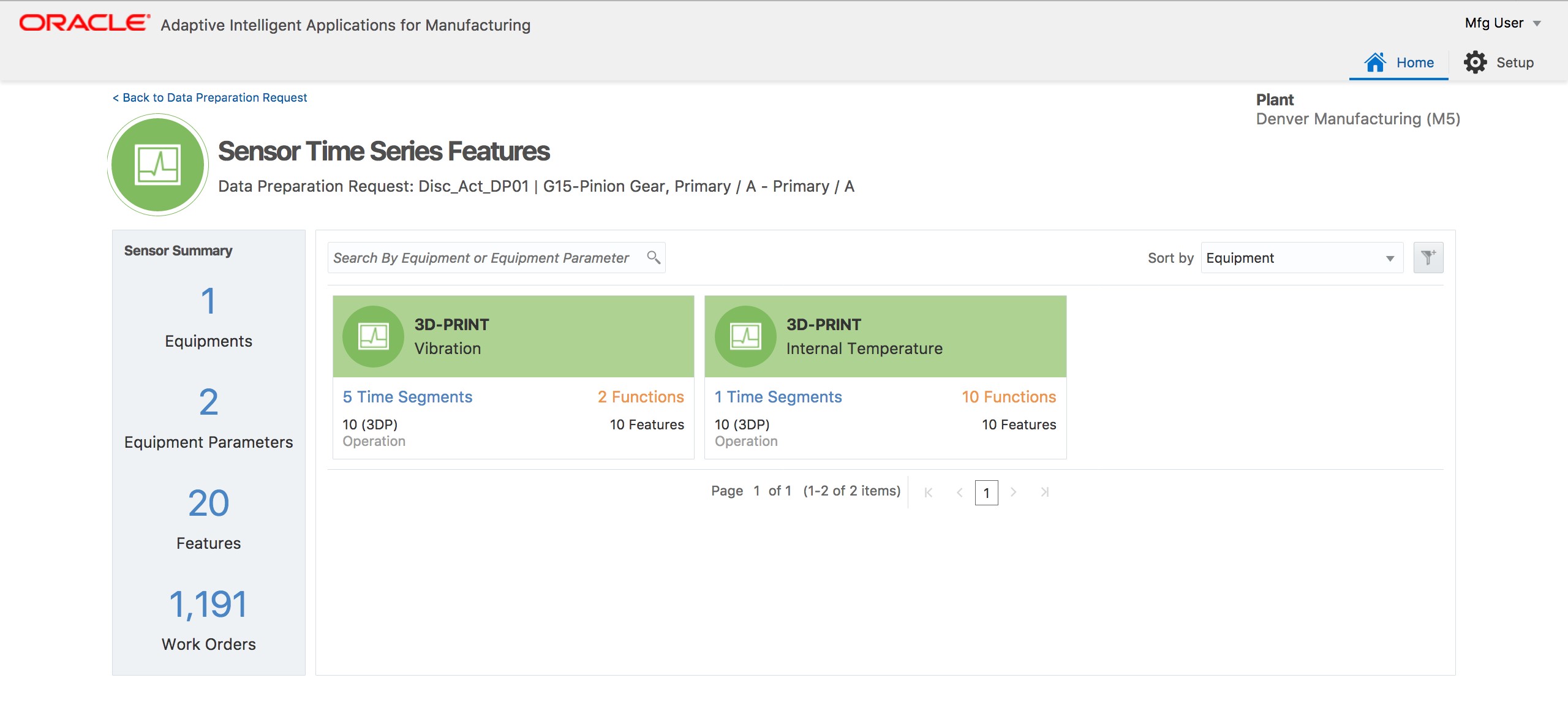

Sensor Time Series Features Screen

Sensor Time Series Feature UI provides following:

- Summary of all equipment, equipment parameters, features computed and the total number of work orders from the data set created using data preparation request.

- Individual tiles for each equipment process parameter with the number of features and the basis number of time segments and functions along with the context operation. Each tile is drillable to see the feature values across work orders in the dataset.

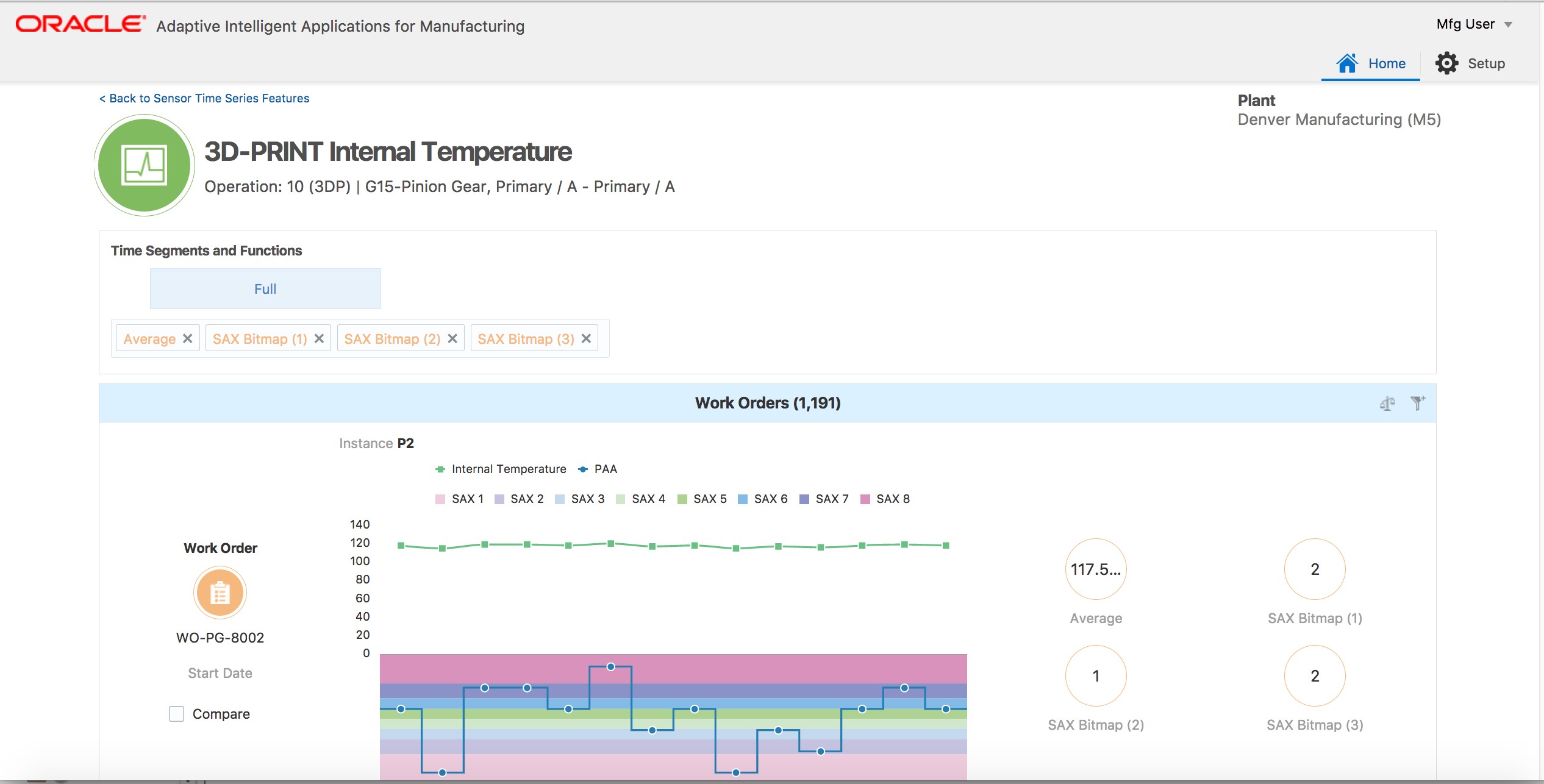

Sensor Summary Results Screen

Sensor Summary Results UI provides following:

- For a given time segment, the sensor time series data points for each process parameter and the SAX (Symbolic Aggregate approXimation) format of the sensor time series data for each work order in the data set. User can discover the patterns visually over the time series charts.

- For a given time segment, the values of the summary functions computed for all time series features for each work order in the data set. User can choose few work orders and compare the values across work orders to understand the differences in the feature values.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

It is recommended to chose the wider work order completion date range having different variation of the data. Data mining analysis gives the best results when the volume and variations are rich in the data.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Preparing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

It provides a simple and intuitive model building framework to allow data scientists to build, evaluate and deploy data mining models such as such as:

- Feature Significance Model. This model extracts the most influential factors (from a list of hundreds and possibly thousands of input factors) that affect a given target variable such as Yield, Quality Test, Cycle Time, Cost etc.

- Insights Model. This model identifies the significant patterns and correlations between the input factors and the output target variable that is being analyzed for a context of a given period of historical data and product.

- Predictions Model. This model identifies conditions under which predictions are made for a target variable by considering various input variables/predictors.

After the successful creation of data prep request, data analyst or data scientist can build models to achieve different analysis such as Feature Significance, Insights and Predictions. The easy to use interface allows data scientist to easily drag and drop the features required, algorithm and parameters in building the models.

Create Analysis Model Screen

Create Analysis Model UI provides following tabs:

- Model Details – Details should include the model name, description and an analysis type which can be either Feature Significance, Insights and Predictions

- Context – It can be one of data preparation request from the list of available requests.

- Output – Based on the production yield or quality analysis, output can be either “work order yield” or “operation yield” for the yield case and a specific quality test element for the quality analysis. The output needs to be classified under different buckets with different ranges.

- Features – This tab lists all the features extracted during the data preparation request. Either all the features and sub set of available features can be selected.

- Algorithm – Chi-Square and Random Forest algorithms are available for the Feature Significance analysis. Apriori and Decision Trees are available for the Insights analysis. Decision Trees and Support Vector Machine algorithms are available for the Predictions analysis.

- Deployment – The Insights and Feature Significance models can be configured to automatically deploy after the successful build. The predictions model can be configured to run at a certain frequency after the model is deployed.

- Summary – The Summary tab provides all the details of the previous tabs in a single view.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

- It is recommended to build the feature significance models to understand the significant features before building the insights and predictions models.

- The classification bins given for the output should not overlap and it is recommended to set up the bins as per the control limits of the quality tests.

- Data Scientist can tweak algorithm parameters as per the data set.

- There can only be one predictions model that can be deployed for a given context and output/target measure.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Analyzing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

After the successful creation of feature significance models, data analyst or data scientist can search for models and review the significant features that are ranked out of the analysis of a specific model.

View Significant Features Screen

Significant Feature UI provides following:

- Significance Summary – Summary about the number of features that are significant out of the total features analyzed and the number of features having the strong influence with the target measure.

- Significant features – list displays the ranked features with the strength of the influence. Each feature can further be analyzed using the descriptive statistics and the statistical graphs like histogram and box plot.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

Significant features are ranked with respect to the strength of the influence of the feature to a specific output or target measure.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Analyzing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

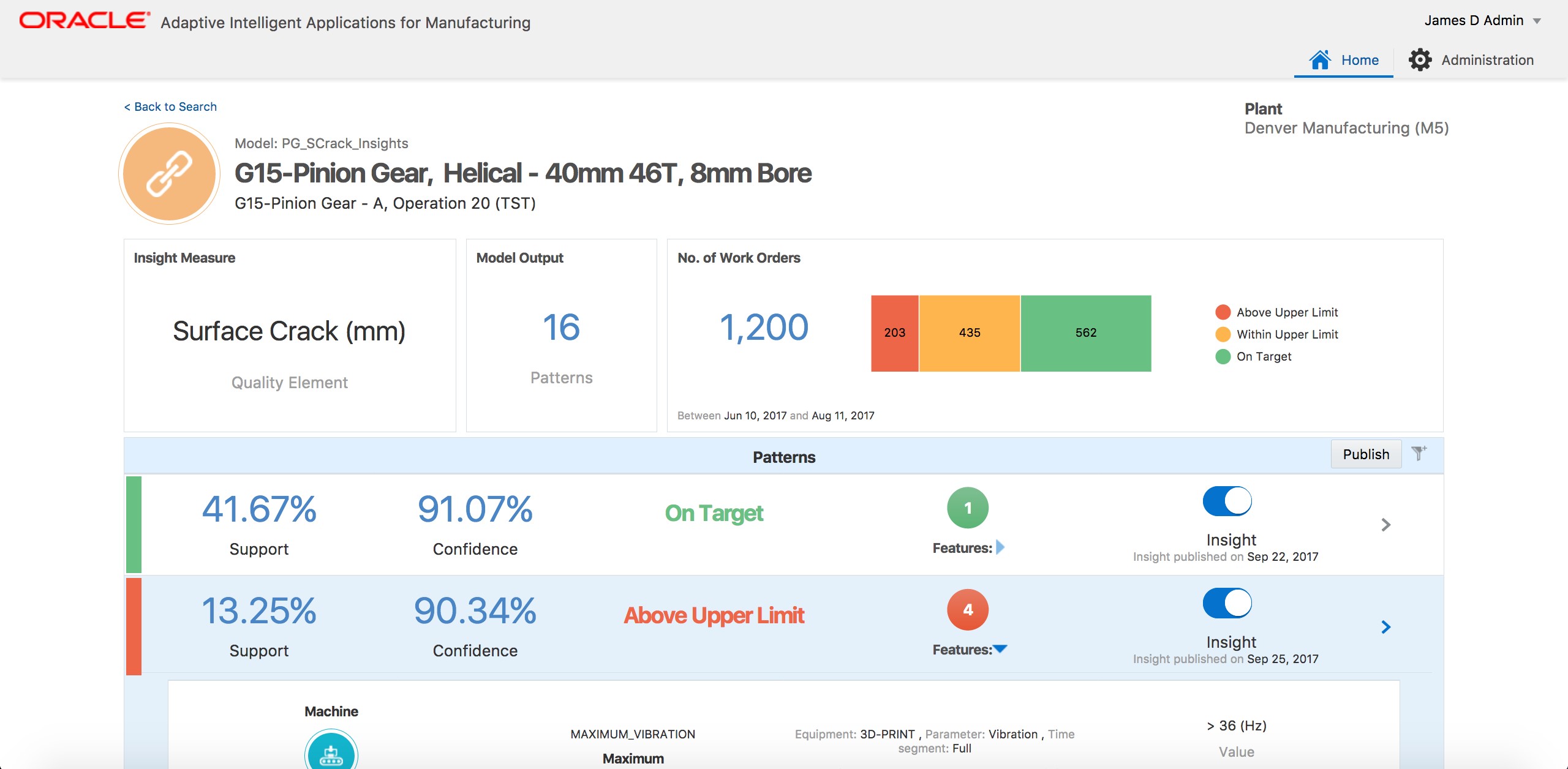

Evaluate Patterns from Insight Models

After the successful creation of insight models, data analyst or data scientist can search for models and review the patterns generated out of the analysis of a specific model.

View Patterns & Correlations Screen

Patterns & Correlations UI provides following:

- Pattern Summary – Summary about the total number of patterns generated, total number of work orders analyzed and the number of work order under each classification of the target measure of the insight model

- Patterns – The list of hidden patterns are provided with the details of the support and confidence for each of the pattern, pattern output classification, the features influencing each of the output classification with the feature range values.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

Data scientist should review the patterns generated with the help of a business analyst having the business understanding and can publish the top 10 valid patterns as insights to the business user.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Analyzing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

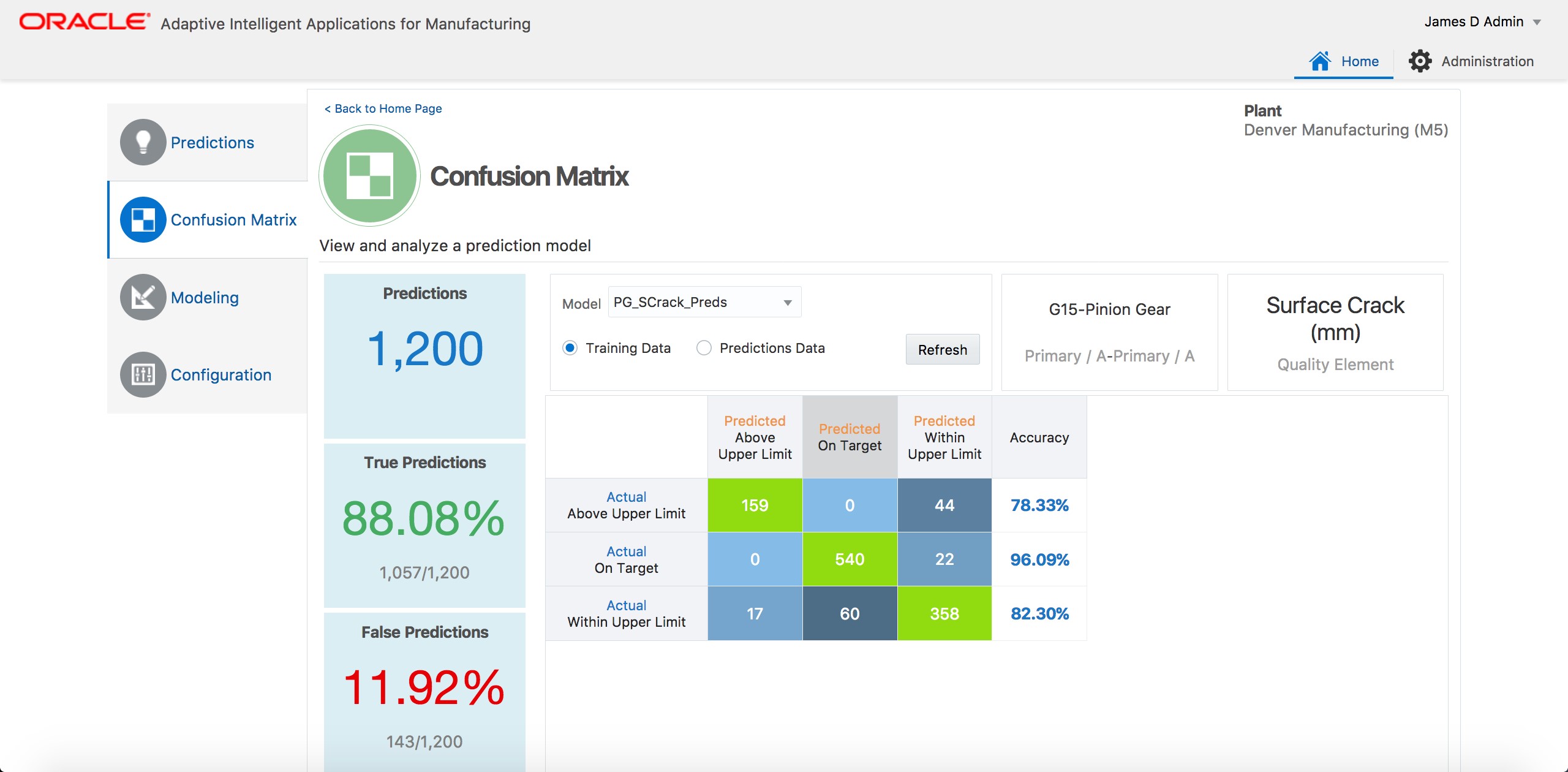

After the successful creation of prediction models, data analyst or data scientist can search for models and review the accuracy of the model using confusion matrix for a specific model.

Confusion Matrix Screen

Confusion Matrix UI provides following:

- Prediction Summary – Summary about the total number of predictions, true predictions% (accurate predictions/total predictions) , false predictions% (inaccurate prediction/total predictions)

- Confusion Matrix – can be reviewed for a given training data (all the historical work orders considered for the analysis) or for the predictions data (for all the production running work orders). The Actual data values are represented in rows and the predicted values are represented in columns for each of the classifications defined in the model. Prediction accuracy is generated for each of the classification.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

After training the prediction model on the training data set, it is recommended to deploy a test production for few months to evaluate and compare the accuracy before moving the model to the production.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Analyzing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

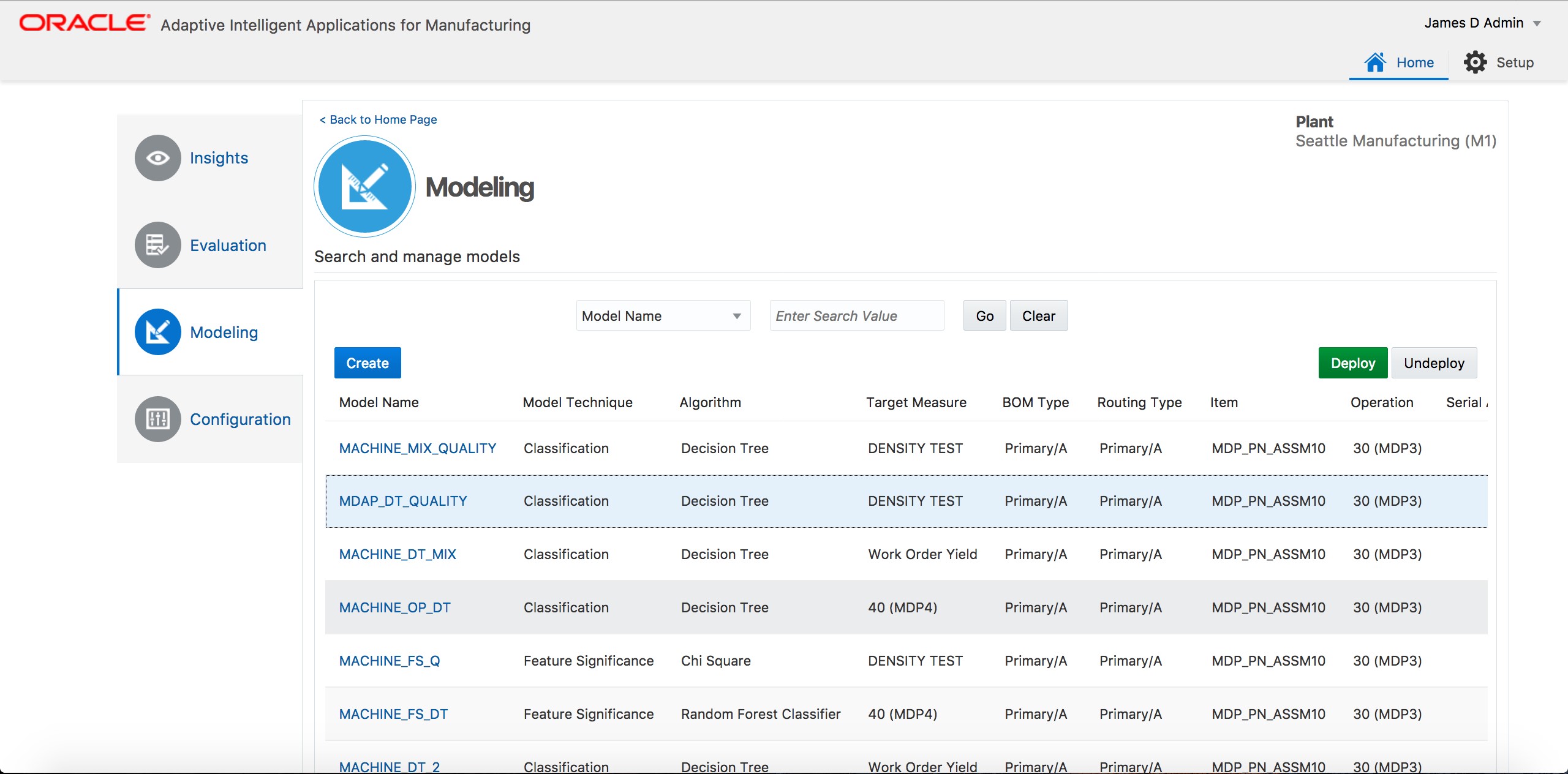

After the successful evaluation of analysis models, data analyst or data scientist can deploy the right models in the production by search and deploy a specific model. Users can deploy any number of Insights models for a given context but there can only be one predictions model and one feature significance model deployed for a given context and output combination.

Model Deploy Screen

Model Deploy UI provides following:

- Search and Manage Models – Users can search for models by model name, item name, bom type etc

- Deploy Models – User can choose a specific model and select deploy or un deploy.

Steps to Enable

Navigate to Setup to create a new user and associate the Application Administrator/Data Analyst/Data Scientist role to be able to access the UI.

Tips and Considerations

It is recommended to deploy the models on the test instance and evaluate the performance before deploying the same to the production instance.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Analyzing Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Oracle Adaptive Intelligent Applications for Manufacturing presents the results of the data mining analysis to business analysts and business users in an intuitive and simple to understand user interfaces.

- Insights from Historical Data Analysis – It provides business users with the hidden insights on influencing factors impacting the production key metrics from the analysis of the historical data.

- Predictions from Current Production Data Analysis – It provides business users with the predictions about the production key metrics and comprehensive details on the influencing predictors.

- Genealogy and Trace – It provides business users with the network view and time line view depicting the entire supply chain of events that can be derived from both historical and current production data.

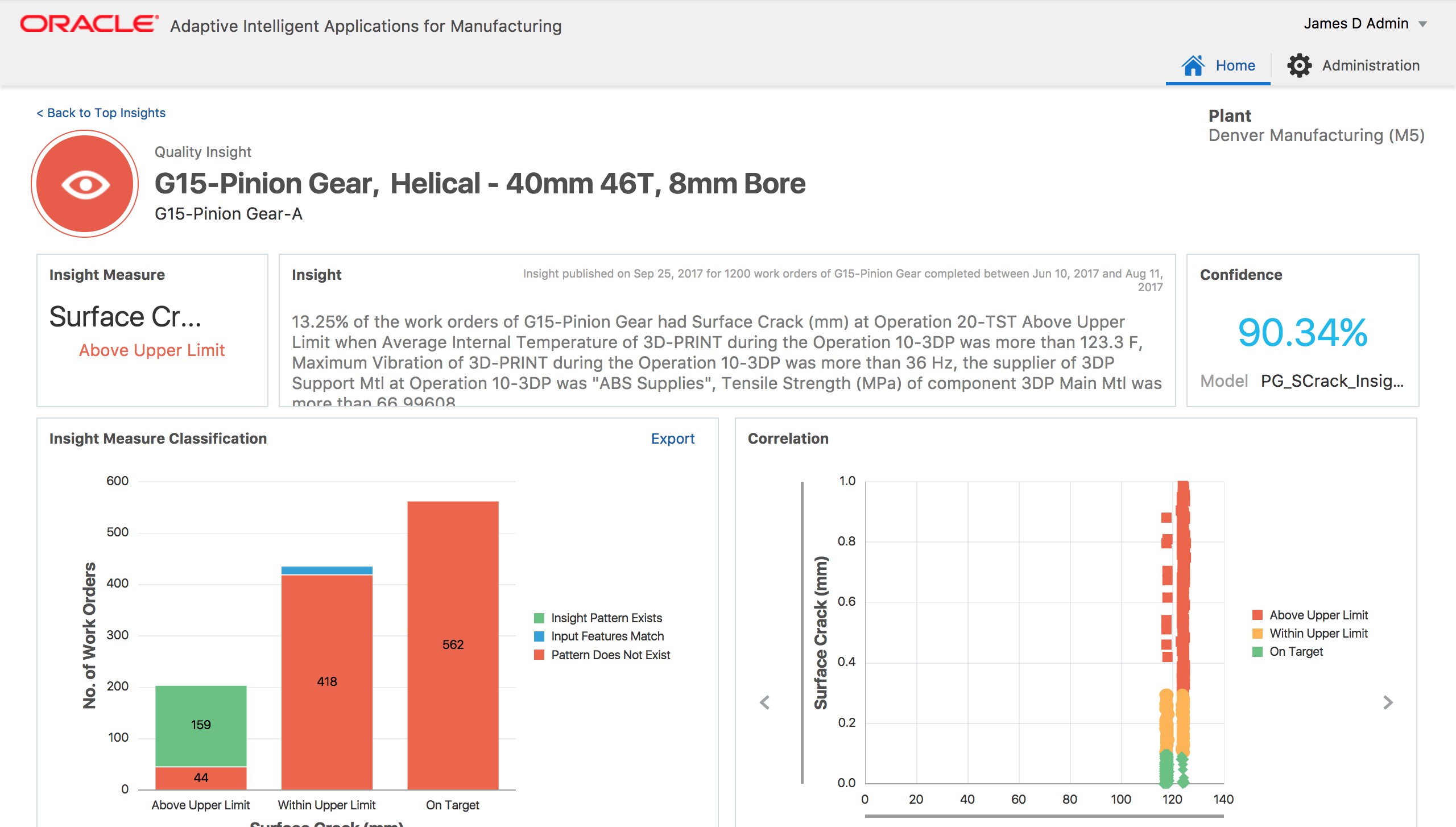

Insights from Historical Data Analysis

The solution provides business users with the hidden insights on influencing factors impacting the production key metrics that are discovered from data mining analysis of the historical data. The insights are available to the users after the patterns are published as insights though the deployed insight models. The insights can also be exported to the third party systems using the outbound service APIs.

Quality Insights Screen

The insights landing page presents the insights under different chapters like Quality, Yield for Discrete and Process manufacturing and Quality, Yield, Serial Unit Quality and Serial Unit Yield for the serialized manufacturing. User can drill into a specific chapter to review all the insights across products in an organization. The Insights page for a specific chapter provides the following:

- Insight Summary – Summary about the total number of insights under the chapter, top three insights

- Insights – list of insights with Factors Influence%, Insight classification, influencing factors for the insight classification.

Insight Details Screen

The insight details UI presents comprehensive details around the influencing factors on how they impact the output by showing the correlation and distribution of the factors with the output/target measure in the historical dataset. The Insight details page provides the following:

- Factors Influence % – The percentage of records where the insight matches in the historical data out of the records having the influencing criteria match

- Insight Measure Classification – Data distribution of the records with respect to the number of records where the insight matches, the records where the input feature match and the record where the insight pattern does not exist.

- Correlation graph – This graphs presents correlation or the distribution for each feature to the output/target measure from the historical data set analyzed.

- Insight Timeline – This graph presents the timeline of the Insight presenting on the output/target measure values recorded for each day.

Steps to Enable

Navigate to Setup to create a new user and associate the Business User/Data Analyst/Data Scientist/ Application Administrator role to be able to access the UI.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Presenting Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Predictions from Current Production Analysis

The solution provides business users with the prediction alerts generated from the analysis of current production data enabling users to detect the potential problems related to the product quality and yield early in the production life cycle before the production is impacted. The predictions dashboard provides comprehensive details on production issues, enlighten on the influencing factors thus empowering users with a window of opportunity to take corrective action based on predictions. The predictions details can also be exported to the third party systems using the outbound service APIs.

Quality Predictions Screen

The Predictions landing page presents the predictions under different chapters like Quality, Yield for Discrete and Process manufacturing and Quality, Yield, Serial Unit Quality and Serial Unit Yield for the serialized manufacturing. User can drill into a specific chapter to review all the predictions across products in an organization. The predictions page for a specific chapter provides the following:

- Predictions Summary – Summary about the total number of products, total number of work orders, quality elements being predicted including the total number of running predictive models.

- Metrics on Predictions – Total number of quality predictions under each classification along with the top n quality element predictions and sunburst showing the predictions across product across classifications.

Prediction Details Screen

User can drill into a specific running work order operation prediction to view the comprehensive details around influencing factors causing the output to fall under a predicted classification. The prediction details screen provides the following:

- Classification Details – The probability for each classification and the prediction probability is presented.

- Predictors – The details of the influencing factors with their rank and prediction influence is presented.

- Prediction Timeline – The time line provides the prediction results over a period of time enabling users to understand the time points of the prediction changes.

- Other Predictions – User will also have a purview of the other quality element predictions for the same work order and the prediction results for the similar work orders is displayed.

Steps to Enable

Navigate to Setup to create a new user and associate the Business User/Data Analyst/Data Scientist/ Application Administrator role to be able to access the UI.

Tips and Considerations

While deploying the prediction models, prediction frequency has to be setup so that the predictor data is available for the model when it runs.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Presenting Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Oracle Adaptive Intelligent Applications for Manufacturing solution provides the centralized visibility for tracking the critical quality issues of partially finished or finished products during the entire supply chain. With the advanced visualizations of connected network view and timeline view, it simplifies the tracing of entire genealogy of items and exploration of key events in production and keep track of the transactions spanning the entire supply chain.

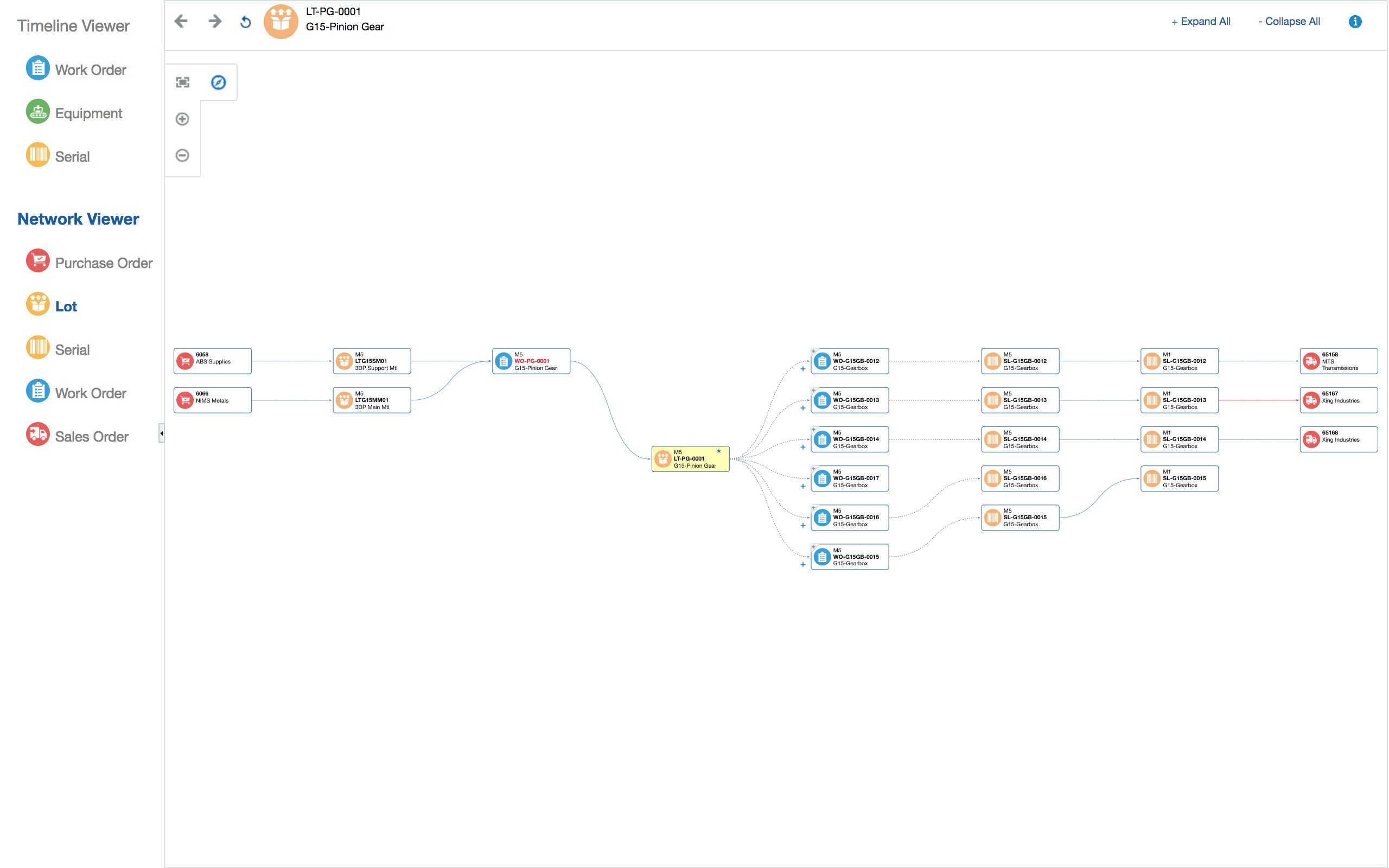

Network Viewer Screen

The connected network view enables easy and interactive tracing of an item during the entire supply chain life cycle showing the details of components procured (internally or externally), consumed, products manufactured, outsourced, products shipped, returned, repaired, serviced in the field and re-shipped. User can easily identify the root cause of quality issues related to supplier material composition, production process parameters, machining issues by navigating between nodes.

Timeline Viewer Screen

Timeline view complements the Network view to help users drill down into a specific work order or a machine or a serial to explore the key events that happened during production. All the timed events related to production operations, material issues, resource usage, quality results and process parameter readings from sensor devices are presented for the entire period of production start to end. In case of machine, it will display machine alerts and key production events

Steps to Enable

Navigate to Setup to create a new user and associate the Business User/Data Analyst/Application Administrator role to be able to access the UI.

Tips and Considerations

User can add custom nodes using web services to connect them to the seeded nodes provided out of the box.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Presenting Data in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Managing Security and Access Control

Oracle Adaptive Intelligent Applications for Manufacturing provides authentication and authorized access to the application by defining the users and assigning predefined roles to provide access to the various functions of the application. It provides users controlled access to the organizations and enables users to configure user level settings or preferences for each module.

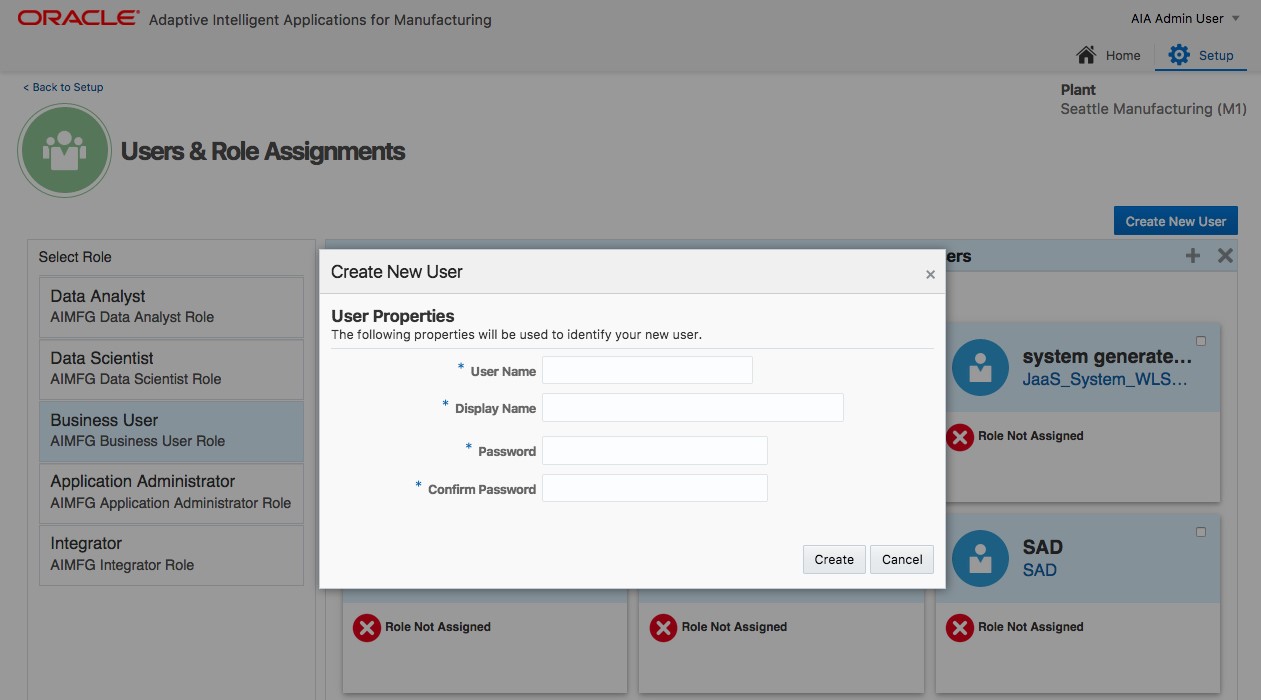

User Roles and Organization Access

Oracle Adaptive Intelligent Applications for Manufacturing enables the users with Application Administrator role to define users. The users can be assigned with the pre-defined roles like Application Administrator, Data Scientist, Data Analyst, Business User and Data Integrator to enable access to the different functions of the application.

Users & Role Assignments Screen

Users & Role Assignments screen provides Application Administrator the ability to add new users and also provides the seeded roles to which Administrator can assign users, revoke users, assign group of users and revoke a group of users.

Organization Access Screen

Organization Access UI provides Application Administrator to manage application user’s access to analysis data and dashboard contents by assigning user to multiple organizations depending on application data access and security requirements.

Steps to Enable

Using Users & Role Assignments UI, create users and associate roles to the users. Using Organization Access UI, assign organizations to users.

Tips and Considerations

Please refer to the list of functions accessible for various roles under Appendix A.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Managing Security and Access Control in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

The application provides users to set up user level preferences to specify how information is displayed in the dashboards available for analyzing insights, genealogy and trace, predictions, and factory status.

User Preferences Screen

Using User preferences UI, user has to select a specific organization, category set which acts as the context for presenting the analysis results in the dashboards.

Steps to Enable

Under user name, choose the preferences.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Managing Security and Access Control in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Oracle Adaptive Intelligent Applications for Manufacturing provides background processes to contextualize the time series sensor data, to summarize the time series sensor data, to purge the time series data and to extract the oracle quality data.

- Contextualization and Event Detection of Stream Data

- Contextualization and Summarization of Alerts Data

- Summarize Sensor Data for Discrete Manufacturing

- Summarize Sensor Data for Process Manufacturing

- Purge Time Series SAX Data

- Extract and Load Quality Data for Discrete Manufacturing

- Extract and Load Quality Data for Process Manufacturing

- Background Process UI provides administrators to search and manage background processes submitted by viewing the progress, error log records etc. Administrator can also submit a new request and schedule the request for either immediate or later run.

Background Process Screen

Steps to Enable

Using Users & Role Assignments UI, create users and associate Application Administrator role to the users as the background processes is accessible only to Administrator role.

Key Resources

- Please see the My Oracle Support Document Id: DOC ID 2388744.1

- For more details please see chapter on Background Processes in Oracle® Adaptive Intelligent Apps for Manufacturing – Part Number E88122-02

Appendix A: Function Security Privileges and Aggregate Privileges

Pre-defined roles have been provided for access to the Oracle Adaptive Intelligent Applications for Manufacturing. The roles and the functions they have access to are described below. A user can be assigned one or more roles.

Table A-1 Oracle Adaptive Intelligent Applications for Manufacturing Roles

| Role |

Function |

|---|---|

| Business User AIMFG Business User Role |

This role grants a user complete access to Predictions, Insights, Genealogy and Trace and Factory Command Center dashboards pages. |

| Data Analyst AIMFG Data Analyst Role |

This role grants a user complete access to Predictions, Insights, Genealogy and Trace and Factory Command Center dashboards pages. This role also grants access to Modelling, Model Evaluation and Data Preparation pages. |

| Data Scientist AIMFG Data Scientist Role |

This role grants a user complete access to Configuration, Time Series Feature Sets, Sensor Device, Modelling, Model Evaluation, Insights and Predictions dashboards pages. |

| Application Administrator AIMFG Application Administrator Role |

This role grants a user administrative access to the application. The administrator will have complete access to all functions of the application. This includes all the tabs (Background Process, Security and Configuration) of the Administration page through which the administrator will be able to manage background processed, organization access and application setup. |

| Data Integrator AIMFG Data Integrator Role |

This role grants a user data integrator access to the application. The Data Integrator can access REST APIs to copy data between systems. |

---

Copyright © 2018, Oracle and/or its affiliates. All rights reserved.

This document is provided for information purposes only, and the contents hereof are subject to change without notice. This document is not warranted to be error-free, nor subject to any other warranties or conditions, whether expressed orally or implied in law, including implied warranties and conditions of merchantability or fitness for a particular purpose. We specifically disclaim any liability with respect to this document, and no contractual obligations are formed either directly or indirectly by this document. This document may not be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without our prior written permission.

Oracle and Java are registered trademarks of Oracle and/or its affiliates. Other names may be trademarks of their respective owners.

Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation. All SPARC trademarks are used under license and are trademarks or registered trademarks of SPARC International, Inc. AMD, Opteron, the AMD logo, and the AMD Opteron logo are trademarks or registered trademarks of Advanced Micro Devices. UNIX is a registered trademark of The Open Group.