- Revision History

- Overview

- Feature Summary

- Transportation and Global Trade Management

-

- Transportation and Global Trade Platform

- Oracle Transportation Management (Base)

- Order Management

-

- Order Release Constraints Ocean Sail Dates and Voyage ID

- Pack with Group

- Ready To Ship Action On Large A Number Of Order Base Lines

- Multi-Select View Related Order Releases Action on Buy Shipments

- Include TiHi THUs on Packaged Item in THU Profile

- Property to Turn Off Logic Setting Order Release Item Out of Date Status

- Property to Turn Off Logic Setting Order Release Known Shipper Value from Order Base

- Add Ship Unit Content to Order Movement XML

- Equipment Reference Units

- Rating And Rate Service

- Booking And Tendering

-

- Spot Tender Planner View Screen

- Saved Query for Service Providers with Spot Bid Tenders

- Spot Tender Bid Response Proposed Pickup Time

- Require New Spot Bid to Be Greater Than the Existing Bid

- Spot Tender Decline Option for Service Providers

- Spot Bid and Broadcast Tender - Turnoff Withdraw Tender Emails for No Bid

- Selected Shipment Remark Qualifier for Tender Communication

- Logistics Machine Learning

- Transportation Operational Planning

-

- Remnant Order Routing

- Define Location Activity Time by Service Provider(s) and Equipment Group(s)

- Maximum Distance Between Stops Enhancement

- Cluster Merge Enhancement

- Load Configuration 3D Pattern - Active Inactive Check Box

- User Defined Patterns - Consider Full Equipment User Defined Pattern First

- Additional Constraints Considered in Edit Load Config

-

- Freight Payment, Billing, and Claims

- Oracle Fleet Management

- Logistics Digital Assistant

- Global Trade Management (Base)

- Trade Agreements

-

- New Fields Available on Item Qualification

- Rules of Origin Formulae Added to Trade Agreement

- Item Value Lookup During Trade Agreement Qualification

- Origin Lookup During Trade Agreement Qualification

- Qualify for Trade Agreement Action on Item

- Qualify for Trade Agreement Action on Item Origin

- Qualify for Trade Agreement Action on Trade Item Structure

- Qualify for Trade Agreement in Process Management

- Enhancements to View Qualification Report

- Support for Wholly Obtained Items in Qualification Process

- Support for Additional Rules of Origin Rule Types

-

- Trade Compliance

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Product | Feature | Notes |

|---|---|---|---|

| 09 JUN 2023 | Transportation and Global Trade Platform | Optional Feature - Apply Sender Policy Framework (SPF) Checks to Outbound Email |

Removed feature. |

| 25 MAR 2022 | Transportation and Global Trade | Optional Feature - Use Download Link for REST Document Content | Updated document. Revised opt in information. |

| 25 MAR 2022 | Transportation and Global Trade | Optional Feature - UI Refresh - Landing Page, Springboard, Application Shell and Navigator |

Updated document. Revised opt in information. |

| 04 FEB 2022 | Transportation and Global Trade Platform | Optional Feature - Limit Simultaneous SQL Execution | Updated document. Delivered feature in update 21C. |

| 04 FEB 2022 | Transportation and Global Trade Platform | Optional Feature - Limit CSV Export Memory | Updated document. Delivered feature in update 21C. |

| 17 DEC 2021 | Transportation and Global Trade | Optional Feature - UI Refresh - Landing Page, Springboard, Application Shell and Navigator |

Updated document. Revised opt in information. |

| 07 OCT 2021 | Oracle Transportation Management Base | Optional Feature - UI Refresh - Landing Page, Springboard, Application Shell and Navigator | Updated document. Revised feature information. |

| 09 JUL 2021 | Oracle Transportation Management Base | Equipment Reference Unit Rounding Threshold and Rounding Grouping Level | Updated document. Revised feature information. |

| 18 JUN 2021 | Created initial document. |

This guide outlines the information you need to know about new or improved functionality in Oracle Transportation & Global Trade Management Cloud Update 21C. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

GIVE US FEEDBACK

We welcome your comments and suggestions to improve the content. Please send us your feedback to otm-doc_us@oracle.com. Please indicate you are inquiring or providing feedback regarding the Oracle Transportation & Global Trade Management What’s New in Update 21C.

Column Definitions:

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

Transportation and Global Trade Management

Transportation and Global Trade Platform

Optional Feature - UI Refresh - Landing Page, Springboard, Application Shell and Navigator

This feature provides you with a set of UI improvements that are focused on modernizing the look and feel of the UI and improving your navigation through the application. Changes include a new default theme, and improvements to the Landing Page, Springboard, Application Shell, Navigator and Search. This feature is delivered as an optional feature (JET APPLICATION SHELL), with the Opt In value set to TRUE/ON to encourage you to become familiar with the new user experience.

SPRINGBOARD

Springboard

The most immediate change that you will notice is that the default theme for the Springboard has been set to the more modern and stylish Redwood theme, this change provides a vast improvement over the light blue cloud theme provided in early versions.

The Springboard navigation has been improved and now follows a menu based navigation approach, which is similar to approach provided in the Navigator.

In the example below - you will notice when you click on a Springboard Folder (in this case the Financial folder), you now go directly to a menu view where all the folders and links are provided directly vs the folder view provided previously.

New Springboard Navigation

Selecting the Financials folder on the Springboard brings up the following menu options under the Financials folder.

New Springboard Navigation - Financials Menu

Within the menu, folders that contain additional levels are identified with an arrow, clicking on the arrow expands the menu. Clicking on an opened arrow will collapse the expanded menu.

New Springboard Navigation - Financials Menu - Expand Sections

To close the expanded Springboard menu option, you click on the opposing arrows in the upper right corner.

Close Expanded Springboard Menu Option

NAVIGATOR

The Navigator has also been improved in a number of ways.

Expanding and collapsing your menu options is now handled with the arrow/triangle icon.

Navigator Default Settings

In the example below, the Purchase Order section under Order Management has been expanded.

Navigator Expand Menu Option

The new Navigator also provides options for you to Expand All options, Collapse All options or Reset the Navigator view back to the default layout.

In the example below, the Expand All view is shown.

Expand All Menu Options

In the example below, the Collapse All option is shown.

Collapse All Menu Options

In the example below, the Reset option is shown.

Reset the Menu

SEARCH - RECENTLY VIEWED

Search has also been improved and now captures, for your current user session, all of your Recently Viewed Springboard/menu selections. The Recently Viewed list will capture all of your recently viewed activity, most recently viewed first, and will revert to a normal search as you type into the Search window. If your daily usage of the application involves moving between a set of managers, you will find this Recently Viewed feature to be a major time saver.

Search - Recently Viewed

This feature improves user navigation allow for faster access to all areas of the product.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

NOTE: If a menu includes External Links, those links will now open in a New Window when selected in the Navigator, Springboard, and Global Search. In previous versions, external links opened in the same window, now, for security reasons, the external links open in a New Window.

UI Configuration Parameter Retain New Line Format

This feature adds a new parameter - RETAIN NEW LINE FORMAT IN GRID TEXT BOXES - to the UI Configuration Logic Configuration that when set to TRUE will retain your new line formatting when the text is saved to the grid. The parameter value is set to FALSE by default to retain the existing behavior.

The RETAIN NEW LINE FORMAT IN GRID TEXT BOXES parameters is available under the newly added MANAGER LAYOUT section of the UI Configuration Logic Configuration.

RETAIN NEW LINE FORMAT IN GRID TEXT BOXES = FALSE Retains Current Behavior

Below is an example with the Default/existing behavior. You enter a multi-line remark in the edit box, when you save the remark to the grid the new line formatting is not retained and the result is a single line remark saved to the grid.

Existing Behavior Example

One Line Result - New Line Format Not Retained

In the example below, the new behavior is demonstrated. With the parameter - RETAIN NEW LINE FORMAT IN GRID TEXT BOXES - set to TRUE the new line formatting will be retained when the text is saved in the grid.

UI Logic Configuration - Parameter Set to TRUE

Enter Text with New Line Formatting

Text Is Saved in Grid with New Line Formatting

For text that is saved to simple grids and viewed in the edit manager view, this feature provides improved formatting and readability by following the new line formatting that you entered/intended.

Steps to Enable

To take advantage of this new behavior, the RETAIN NEW LINE FORMAT IN GRID TEXT BOXES parameter in your UI Configuration Logic Configuration (set via User Preference or the Default set for the domain) will need to be set to TRUE.

Tips And Considerations

The new line formatting is honored in the Edit Manager Layout, the View Manager Layout will still show the grid entry without the new line formatting. Also - this enhancement applies to simple grids only - like Refnum and Remark, where the grids are editable within the grid. It does not apply to second page grids - grids that open a new page for edit rather than being editable in the grid.

New Line Format Not Honored In View Manager Layout

Screen Set Results Configuration Improvements

This feature provides you with two usability improvements related to setting up your screen set results. When you specify a label name for a column, the original column name is now being retained so that the original field mapping is apparent and now, when you define a pseudo field, the qualifier used for the pseudo field definition is provided so you understand how the pseudo field was defined and the qualifier that was used.

In the example below, labels have been provided for many of the columns (Label ID), note that the original column names in the Column field are still available so the understanding/mapping to the actual column being labeled is retained.

Original Column Names Retained

In the example below, for comparison purposes - you will notice that the label entered in the Label ID column is copied to the column name - so information about the original column being labeled is lost.

Original Behavior - Column Names Set to Label Names

In the example, below a Reference Number Pseudo field is being defined. The Reference Number Qualifier that will be used in this example is Division. After the value is set, both the field used Refnum Value and the Qualifier used - in this case Division - are provided so that you understand how the Pseudo field has been configured.

Pseudo Field Qualifier Information Provided

By comparison, in previous version of OTM - the same Pseudo field setup provide little information about the field and qualifier selected for configuring the Pseudo field.

Pseudo Field Setup in Early Versions

These finder result configuration changes will remove any confusion you may have regarding the columns and qualifier values used in configuring your finder results.

Steps to Enable

You don't need to do anything to enable this feature.

Configurable Results Pop-Up for Custom Action

This feature provides you with the ability to configure the Result Message Text pop-up that is displayed when running a custom action to something that is more meaningful and more directly related to the action being performed. This feature also allows you to set an Auto Close Result Message Timer for the Result Message Text pop-up which, when configured, will eliminate the need for the user to manually close the message pop-up display.

In the example below, both the Result Message Text pop-up and the Auto Close Result Message Time have been configured. When this action (CZ_TEST_ACTION) is run against the order release the configured message will be displayed in the Result Message Text pop-up and the pop-up will automatically close after 5 seconds.

Action Configured with Result Message Text and Auto Close Result Message Timer

Configured Pop-Up - Message Closes After 5 Seconds

The example below shows the current/default behavior. The message provided is generic and is not related to the defined action, and the user is required to minimize the pop-up dialog box.

Default Behavior

Allows you to provide more meaningful messages to your users when running customer actions. This feature also allows the pop-up message provided to be closed automatically, removing the need for the user to take action/minimize the dialog box.

Steps to Enable

To take advantage of this feature you will need to modify (or create) Actions in the Actions Manager (Configuration and Administration > User Configuration > Actions Manager) that contain:

- A meaningful Result Message Text

- An Auto Close Result Message Timer time amount (must be greater than 0)

This feature provides you with a new Bulk Query that you can use in a two-step process to extract a large number of resources in order to feed external reporting tools and/or analytics tools.

With the two-step approach, you will first run a Bulk Query to return a list of PKs that you are interested in retrieving. In the second step, you use the returned list of PKs to perform a detailed resource retrieval for all the PKs returned in the Bulk Query from step 1. Your retrieval process for pulling over the details, should be developed in a way that minimizes the overhead required to run the process i.e., navigate through the list of PKs one at a time vs attempting to extract everything all at once.

Usage:

- Perform bulk query to return a collection of PKs - this will be a new custom action - custom-actions/bulkQueries/{resource name} - return an array of. PKs

- Resource retrieval for a collection of PK values - the "q" string contained in the Advanced Query message body will use a new "in" clause that can be used to query for batches of the PKs returned in a prior Bulk Query.

Bulk Query Example

Provides you with an improved process for identifying and then retrieving larges amount of data using REST.

Steps to Enable

Review the REST service definition in the REST API guides to leverage (available from the Oracle Help Center > your apps service area of interest > APIs & Schema). If you are new to Oracle's REST services you may want to begin with the Quick Start section.

The feature extends the resource querying capabilities for the REST API so that your saved queries will now be able to support 'bind parameters' so that the saved query can now be more of a template query which can be executed with different parameter values substituted within it. For example, abstract queries like "retrieve all order releases with a source location of X" or "retrieve all shipments with a total weight greater than Y", are valid for different values of X and Y for different executions.

For more information regarding the advanced query capabilities provided with the REST APL, please review the REST API for Transportation and Global Trade Management Cloud documentation found on https://docs.oracle.com/en/cloud/saas/transportation/21c/otmra/index.html.

Highlights:

- New property. Prior to this feature the only accepted property in the Query Definition was the "q" query string, now - to support specifying a Saved Query GID which is used to retrieve the resources (for custom-actions/queries) or primary keys (for custom-actions/bulkQueries) - the "copiedFrom" property is now accepted.

- Positional Bind Parameters - For example, "SELECT LOCATION_GID FROM LOCATION WHERE LOCATION_NAME LIKE ? AND DOMAIN_NAME = ?". Allows the query to be executed for different combinations of input parameter values. Bind parameters used in this way are positional so that when substituting values into the template for execution, the number and the position of parameter values are significant; there must be the same number of values as bind markers (the ?) and the first value will be substituted for the first marker, the second value for the second marker and so on.

- Named Bind Parameters - The REST API also supports Saved Queries which specify bind parameters by name. This supports the extra capability to substitute the same named value in multiple places. The named parameters must be a colon - ':' - followed immediately by a lower case alphabetic character and then one or more 'word' characters (lower and upper case alphanumeric and underscore). "SELECT LOCATION_GID FROM LOCATION WHERE LOCATION_NAME LIKE :locName AND DOMAIN_NAME = :domain".

This feature expands and simplifies the query options provided by the REST API.

Steps to Enable

Review the REST service definition in the REST API guides to leverage (available from the Oracle Help Center > your apps service area of interest > APIs & Schema). If you are new to Oracle's REST services you may want to begin with the Quick Start section.

Insert Date and Update Date Provided for Child Resources

This feature provides visibility to the insert date and update date fields for the child resources. Previously, insert date and update date were only provided for root resources, this enhancement, by default, will provide the insert data and update date for child resources as well.

This feature provides you with the ability to query for your child resources based on a specific update or insert date; this will allow you to be more specific when using REST for data extraction purposes.

Steps to Enable

Review the REST service definition in the REST API guides to leverage (available from the Oracle Help Center > your apps service area of interest > APIs & Schema). If you are new to Oracle's REST services you may want to begin with the Quick Start section.

Tips And Considerations

The insert date and update date are now provided by default for child resources. If, for some reason, you need to disable this output, the property glog.fusion.cil.config.childFP when set to false will revert the behavior back to only providing insert date and update date for the root resources.

New/Modified Resources - External System and Order Movement

This feature extends the REST Resources to include the External System. This addition allows you to Get, Post and Update the External System. You will find this enhancement useful in situations where you wish to create/update information about an External System. For example, complementary software providers who require that an external system be setup as part of their on-boarding process will find the REST option easier to manage than having customers manually creating the required external system information.

This feature also expands the operations available for the Order Movement to include Create and Update

Extends the available REST services to better support additional integration scenarios.

Steps to Enable

Review the REST service definition in the REST API guides to leverage (available from the Oracle Help Center > your apps service area of interest > APIs & Schema). If you are new to Oracle's REST services you may want to begin with the Quick Start section.

Tips And Considerations

Note that the External System Password is not available for Get, Post and Update operations.

This feature provides you with an improvement to the "upload" action allowing you to load document content into an existing (previously created) document that does not contain content.

Usage Example:

$ curl -u RESTAPI.ADMIN:CHANGEME -H "Content-Type: image/png" "http://slc17qyj.us.oracle.com:8080/logisticsRestApi/resources/v2/custom-actions/upload/documents/RESTAPI.MTH-DOC-002/contents" --data-binary @google.png

- The Content-Type must match the content of the data being uploaded - in this case it is a PNG image file called "google.png".

- The current File Content Analyzer and Virus Scan logic is enforced with all uploaded content.

- The content can only be uploaded to a pre-existing "documents" resource e.g. in the above example the Document GID of RESTAPI.MTH-DOC-002 must exist.

This feature addresses some limitations in the REST API related to document content upload and download.

Steps to Enable

Review the REST service definition in the REST API guides to leverage (available from the Oracle Help Center > your apps service area of interest > APIs & Schema). If you are new to Oracle's REST services you may want to begin with the Quick Start section.

Tips And Considerations

- The Content-Type must match the content of the data being uploaded.

- The content can only be uploaded to a pre-existing "documents" resource.

Key Resources

- More information about this feature is available in the docs.oracle.com API guide.

Optional Feature - Use Download Link for REST Document Content

This feature, when enabled, will show a link to the document content download action in the standard links collection rather than within the current content child resource. When disabled, the current behavior will continue.

Provides access to the download action within the standard links collection, which is more intuitive and consistent.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- To change the Opt In state for this feature:

- Go to the Optional Feature UI - Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

- Select the USE DOWNLOAD LINK FOR REST DOCUMENT CONTENT Optional Feature.

- Run the desired Action Opt Out or Opt In.

Upload Action Extended to Handle Multiple Documents in a Single Action

This feature enhances the Upload Document action so that you can now select multiple documents to upload in a single upload request.

In the example below, there are four documents to be uploaded against the shipment. All four documents can now be selected and uploaded in a single upload document request.

Upload Action

Multiple Documents Selected for Upload

Selected Documents Ready for Upload

Result - Four Documents Uploaded

This enhancement simplifies the steps required to upload multiple documents.

Steps to Enable

You don't need to do anything to enable this feature.

Oracle Business Intelligence Enterprise Edition (OBIEE) to Oracle Analytics Server (OAS) Upgrade

This feature upgrades the infrastructure used to provide analytics and reporting in OTM and GTM from OBIEE to the latest release of Oracle Analytics Server, or OAS. OAS provides the opportunity, in future releases, to take advantage of the many new features and capabilities provided by this platform.

OAS Main Dash Board - New Look and Feel

DEPRECATED KPI WATCHLIST

Oracle Analytics Server no longer supports KPI Watchlists, which were supported previously with OBIEE. All of the Public Dashboards have been updated to use Gauges as a replacement for the deprecated KPI Watchlist functionality. If you have any custom dashboards that use KPI Watchlists, these dashboards will need to be updated with an alternative/supported approach. As noted, the KPI Watchlists used in all the Public Dashboards have been replaced with Gauges - which is our suggested replacement.

In the example below, for the Main Dashboard, you can see the deprecated KPI Watchlist versus the new Gauge approach used with OAS.

Deprecated KPI Watchlist OBIEE

New Gauge Implementation of KPI Watchlist

.

The upgrade to OAS provides you with excellent data discovery capabilities and a roadmap of future opportunities provided with OAS including Data Visualization, Data enrichment, Machine Learning in Data Flows and many others.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- KPI and KPI Watch List capabilities that were available in OBIEE are not supported in OAS. For your custom dashboards, you will need to replace your existing KPI Indicators (status icons that represent the performance status of a KPI based on threshold values) with Gauges.

- You can refer to this document for details on replacing your KPI Indicators:

- Doc ID: Oracle Transportation and Global Trade Intelligence Cloud Key Performance Indicators (KPI) Replacement Guide (Doc ID 2784313.1).

- All the KPI/KPI Watchlists in the Public dashboard reports have been replaced by new dashboard reports.

- Dashboards and dashboard reports are not translated in OAS.

Key Resources

- You can refer to this document for OAS 5.9 feature availability and comparison with OBIEE 12.2.1.4: https://docs.oracle.com/en/middleware/bi/analytics-server/whats-different-oas/index.html#OASWD-GUID-C907A4B0-FAFD-4F54-905C-D6FCA519C262

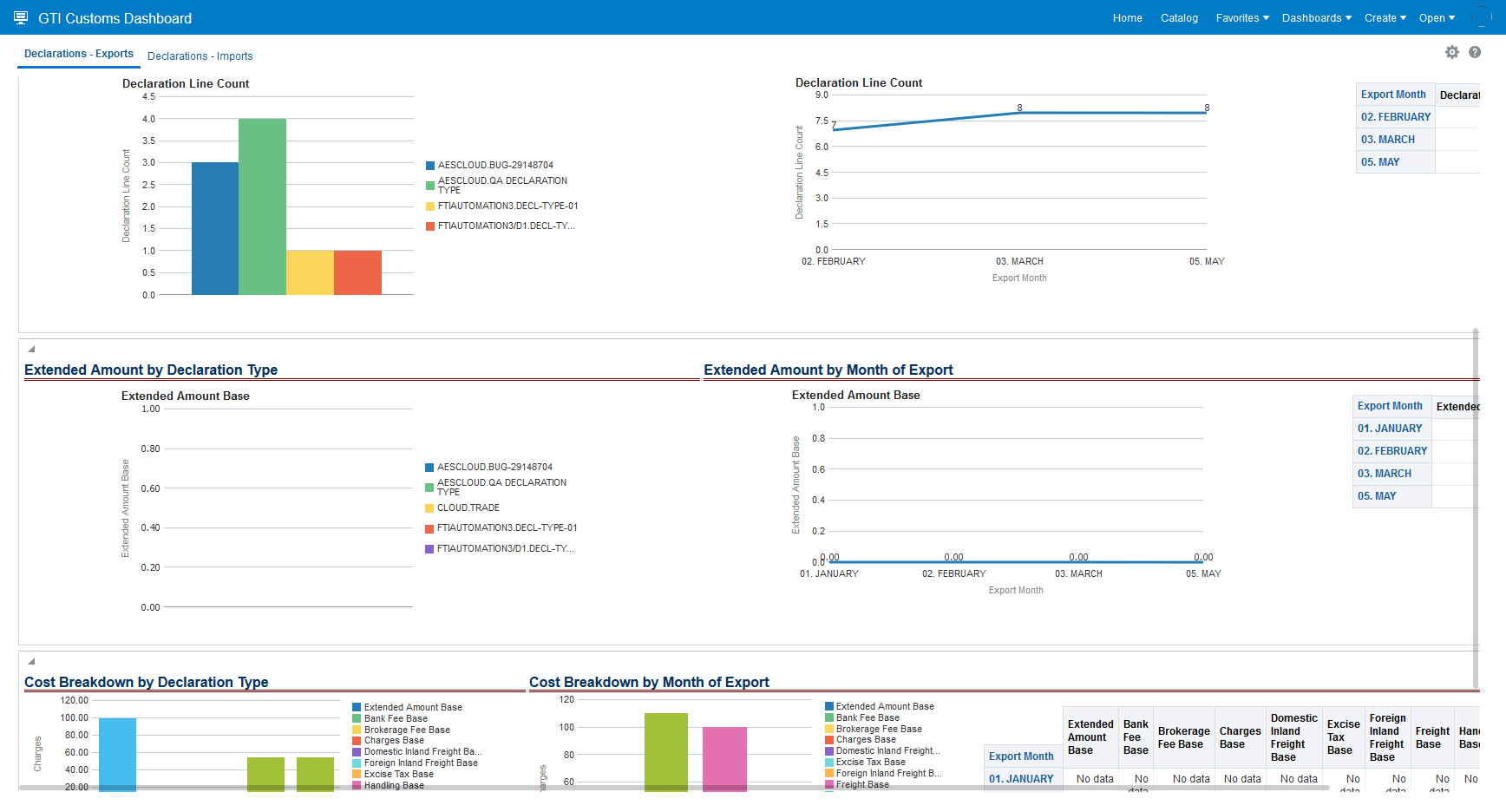

Subject Area-Specific Dashboards and New Dashboard Links

This feature allows you to add subject area specific Dashboard links to your OTM menu. To demonstrate this new capability, a set of subject area specific Dashboards has been provided. The new Public Dashboards include:

- Financials Dashboard,

- Shipment Dashboard,

- Planning Dashboard,

- Logistics Network Modeling Dashboard,

- Fleet Dashboard,

- Machine Learning Dashboard,

- Customs Dashboard,

- Transactions Dashboard.

The new Public Dashboards are available within the associated subject area Springboard and Navigator menus. For example, the Financials Dashboard is provided as a link under the Financials menu.

Financials Dashboard Menu Link

Financials Dashboard

Shipment Dashboard

Planning Dashboard

Logistics Network Modeling Dashboard

Fleet Dashboard

Logistics Machine Learning Dashboard

GTI Customs Dashboard

This feature provides the option to have many Dashboard specific links on your menus, providing easy access to subject area specific information.

Steps to Enable

The Public Dashboards do not require any setup.

You can add your own Dashboard links to your menu by going to Configuration and Administration > User Configuration > Menu Manager.

New/Edit Menu Element - Link

- Enter a name for the Dashboard link in the Text box. This name appears on the menu.

- Dashboard: Select the Dashboard you want to link to.

Add a Dashboard Link

The Metric Notification Profile feature allows you to configure who is notified and the information provided when certain metrics are reached. The feature provides you with options for the log files and the performance metric types to include in the notification.

Navigate to Configuration and Administration > Power Data > Diagnostics > Metric Notification Profile

Metric Notification Profile

In example below, the Metric Notification Profile has been configured to include diagnostic logs, a JRA recording and Heap Dumps. The Attach Performance Diagnostics selection of "Standard" will include most all configuration and performance collectors. You can send the notification via a contact in the system - in this example OTM Support, or to an ad-hoc email address - in this example OTM Tech. The email generated by the system includes an attachment along with a unique file name that you can share with Oracle to help diagnose issues.

Metrics Notification Profile

If you select the "Non-Standard" option for Attach Performance Diagnostics, you can then select the Performance Collection Types you want collected.

Metrics Notification Profile - Attached Performance Diagnostics - Non-Standard

NOTIFY

You can generate the Metric Notification for your Metric Notification Profile by selecting the desired profile(s) and running the Metric Notification Generation action Notify. When you run the Notify action, all contacts and email addresses defined for the selected metric notification profile(s) will receive a communication containing the diagnostics defined within the profile.

This page is accessed via Configuration and Administration > Power Data > Diagnostics > Metric Notification Profile > Notify.

Generate Metric Notification - Run Action

Enter a Reason for generating the notification, the reason appears in the Threshold field of the email generated by the action and click submit.

Generate Metric Notification - Reason

Provides you with the tools required to better monitor and support the overall performance of your OTM/GTM instance.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

The Consolidation Interval field is not used in 21C.

Consolidated Interval Field

Optional Feature - Use Direct SQL for Audit Trail Cleanup

This Optional Feature, when enabled, uses a direct SQL approach for cleaning up audit details when the Audit Trail cleanup process is run. When disabled, the existing EJB bean remove method is used to delete the audit details - this method is a slower less efficient method since the EJB approach loads the records and then deletes it. The SQL approach provides the same functionality, but runs much faster.

The Opt In/Opt Out capability for this feature expires with the 22B update.

When enabled, the direct SQL option provides you with a much faster method for managing the Audit Trail cleanup process.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

If you wish to change the Opt In state for this feature:

- Go to the Optional Feature UI - Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

- Select the USE DIRECT SQL FOR AUDIT CLEANUP Optional Feature.

- Run the desired Action Opt Out or Opt In.

Optional Feature - Limit Simultaneous SQL Execution

When this Optional Feature is enabled, users are limited to the total number of simultaneous queries, the number of simultaneous queries for a particular user session, and the total number of cells returned by a query.

The Opt In/Opt Out capability for this feature expires with the 22C update.

When enabled, the Limit Simultaneous SQL Execution protects the performance of the system by limiting the SQL execution initiated by a single user.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

If you wish to change the Opt In state for this feature:

- Go to the Optional Feature UI - Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

- Select the LIMIT SIMULTANEOUS SQL EXECUTION Optional Feature.

- Run the desired Action Opt Out or Opt In.

Optional Feature - Limit CSV Export Memory

This Optional Feature, when enabled, will stop repeated calls from a single user to CSV Export before the first export call completes.

The Opt In/Opt Out capability for this feature expires with the 22C update.

When enabled, the Limit CSV Export Memory protects the performance of the system by limiting the simultaneous CSV exports initiated by a single user.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- While the manager for these features refers to them as "optional" - each of these features will become mandatory when the Optional Until update is released. The optional aspect of these features refers to the period of time where there is an opportunity to Opt In/Opt Out of enabling the feature. During this "optional" period - the time between when the feature is released and the release prior to the Optional Until release - the request/desire/intention is for you to enable the feature(s) for testing purposes so that the transition to mandatory, as of the Optional Until release, is uneventful.

If you wish to change the Opt In state for this feature:

- Go to the Optional Feature UI - Configuration and Administration > Property Management > Optional Features.

NOTE: Only the DBA.ADMIN user can access and use the Optional Features page.

- Select the LIMIT CSV EXPORT MEMORY Optional Feature.

- Run the desired Action Opt Out or Opt In.

Oracle Transportation Management (Base)

Order Release Constraints Ocean Sail Dates and Voyage ID

This feature allows you to specify, on your order release, the Early Sail Date, Late Sail Date or Voyage ID that should be considered on the primary leg/ocean leg when the order is planned.

The Order Release Constraints Tab now supports the ability for you to constrain - for the primary leg/ocean leg portion of a route, the voyage schedule(s) that will be considered in planning. You can constrain the voyage schedules by date - Early Sail Date, Late Sail Date - or you can specify a specific Voyage ID you want the order to use.

Sail Dates and Voyage ID New Order Release Constraints

In the example below, the order release is planned without any constraints and is scheduled to ship on the earliest available voyage schedule - in this case the voyage sailing on May 10, 2021.

No Sail Date Constraints

In the example below, the order release is now constrained so that it must ship on a voyage that leaves no earlier than June 8, 2021. This is accomplished by specifying the Early Sail Date as shown below.

Early Sail Date Constraint

The planning result - given the Early Sail Date constraint of June 8, 2021 - is below. The earliest voyage after the Early Sail Date specified on the order is for June 14th, and this is now the assigned voyage.

Early Sail Date Constraint Solution

In the example below a specific voyage - Voyage ID USNYCTOBEANR_OC_2021WK28 - which departs from USNYC on July 12th, is assigned to the order release.

Voyage ID Constraint

The planning result - given the specified Voyage ID - provides the expected result below - the planned ocean shipment is using the Voyage ID specified on the order USNYCTOBEANR_OC_2021WK28.

Voyage ID Constraint Solution

In the example below - the order has a specified pickup window - in this scenario the order must be picked up between May 10th and May 14th - but the order cannot be schedule on an export vessel voyage any earlier than June 15, 2021.

Order Pickup Date Constraint

Early Sail Date Constraint

The planning result - given the pickup date constraint on the order to pick up between May 10th and May 14th coupled with the Early Sail Date constraint of June 15th provides the desired result. The drayage shipment supports the pickup activity meeting the pickup requirements - between May 10th and May 14th, and the ocean shipment is assigned to a voyage that sails after the Early Sail Date of June 15th.

Order Pickup Date Requirements and Early Sail Date Solution

In the example below, three orders are picked up on three different weeks in June (June 14, 21, 28) - these orders are all assigned to the same Voyage ID that sails on July 26th. OTM plans the pickups across the three weeks, and consolidates the containers into a single ocean shipment that has been planned using the specified Voyage ID on the three orders.

Order Pickup Dates Across Weeks - Same Voyage ID

In the scenario below - the orders are booked into an available FCL Consol shipments using the action Build Buy Shipment On Primary Leg Show Consol Options.

For more information on the setup and usage of FCL Consol shipments see the OCEAN FCL CONSOL ENHANCEMENT from the 20C What's New.

In this setup, there are three available Consol Shipments. The first two consol shipments are voyage specific consols with sail dates of June 7th and July 12th, while the third consol shipment is date range specific consol sailing on August 2nd.

Available Consol Shipments

Setting the Early and Late Sail Dates on the order and/or specifying the specific Voyage ID provides you with the ability to guide/limit the set of consol shipments considered when planning your order releases.

In the example below the order Early Sail Date is set to July 1st - which reduces the FCL Consols considered/available to the two Consols available after that date.

FCL Consol Shipments Available Constrained by Early Sail Date

In the example below, the order is constrained to a specific Voyage ID - and only the FCL Consol shipment assigned to that voyage is presented as an option.

FCL Consol Shipments Available Constrained by Voyage ID

SNRO-OCEAN

When you run SNRO-Ocean against orders that contain a Sail Date or Voyage constraint - the options provided will be constrained by the constraints that are on the order release.

CUTOFF TIMES AND ARBITRARIES

For scenarios where your setup involves cutoff times and/or inland arbitraries - the sail date constraint is correctly honored considering the voyage sail date. In both the cutoff time and inland arbitrary case, the ocean shipment's start time will be earlier than the sail date/time to accommodate the cutoff time requirement and/or an inland arbitrary pickup requirement, in this case OTM will correctly honor the voyage sail date constraint versus just considering the ocean shipment's start time..

Allows you to guide the selection of viable ocean voyages for your order releases by either specifying a specific Voyage ID to use or guiding the voyage selection based on a desired/required Early Sale Date and/or Late Sail Date range.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

In scenarios where your order planning window is wide open i.e., no order dates for Early Pickup Date or Late Delivery Date are specified, there is a possibility that your order planning window time span will be greater than the 30 day default value set for the ORDER MANAGEMENT parameter ORDER WINDOW TIME SPAN.

For example - if you're planning an order today, with an the early sail date that's 35 days from now and is to be assigned to a voyage that's has a 12 day transit time, then this order would require an ORDER WINDOW TIME SPAN value of at least 47 days.

If you have scenarios where you do not specify the Early Pickup Date and Late Pickup Date on your orders and your orders have requirements for sailing dates that are more than 30 days out, we recommend setting the ORDER WINDOW TIME SPAN to a value greater than the default, but as small as necessary to work for your situation.

Note that if your orders have the Early Pickup Date and Late Delivery Date specified then the ORDER WINDOW TIME SPAN parameter does not come into play.

This feature allows you to identify a Pack With Group on your order lines so that packing - using AutoCalc - can be guided by the Pack With Group values you specify.

By specifying a Pack With Group on your order lines, you can guide OTM's ship unit packing logic to follow external packing requirements. For example - in a Ready To Ship scenario where multiple lines are released from multiple POs onto a single order release - you may wish to keep the lines from the different POs segregated versus having OTM pack the multiple lines together on a single ship unit. In another situation - where OTM only has visibility to the linehaul portion of a two leg delivery operation - OTM's packing options from the origin to your cross dock location, while desirable for the linehaul portion of the journey, maybe overly aggressive if the operation is not interested in breaking down pallets at the cross dock for the final cross dock to the customer destination(s) portion of the journey. In this scenario, you can use the Pack With Group to pack your ship units considering the downstream customer delivery requirements versus packing the ship units just considering the source to destination (cross dock in this case) option.

In the example below - the order release contains three lines with the same packaged item coming from two different purchase orders. When no Pack With Group on the order lines, OTM places the three order lines into one ship unit. If the desired solution is to have a separate ship unit for each of the purchase orders related to the order lines, then specifying a Pack With Group for the POs involved will provide the desired packing result where the lines are packed separately by PO.

Below is the ship unit packing solution when no Pack With Group information is specified on the order lines. In this case, OTM generates one ship unit for the three order lines.

No Pack with Group Specified One Ship Unit Three Lines

In the example below, a Pack With Group has been provided for each of the order lines. When the Generate Ship Units action is run against this order the ship unit packing is now done considering the Pack With Group values entered on the order lines. In this case, two groups are created one for Pack With Group PO1 with two order lines and another for Pack With Group PO2 with one order line.

Pack with Group Specified Two Ship Units Packing by Pack with Group

Pack with Group Specified Two Ship Units Packing by Pack with Group

By default, the Pack With Group will be considered in the repacking done by planning. There are some situations where you may want to ignore the Pack With Group when repacking the shipment ship unit. In this case, you can control whether the Pack With Group is considered - or not - by setting the logic configuration parameter REPACK SSU IGNORE PACK WITH GROUP. The default value is FALSE, meaning that by default the Pack With Group information will be considered. When this parameter is set to TRUE, the Pack With Group will be ignored during the shipment Ship Unit Repacking. The logic here is that you may wish to be more aggressive during the shipment ship unit repacking than order ship unit building by consolidating partials with different pack with groups into the same shipment ship unit.

Repack SSU Ignore Pack with Group Parameter

Provides you with additional control over how the ship unit packing is done in OTM to satisfy your operational requirements.

Steps to Enable

To use this feature you will need to :

- Create an order release where the Order Configuration is Auto Calc

- Enter the desired Pack With Group information on your order release lines

- Generate the ship units for the order release - either automatically or via the Generate Ship Units action

Ready To Ship Action On Large A Number Of Order Base Lines

This feature allows you to configure OTM so that your Ready To Ship scenarios that involve a large number of lines can be processed. Specifically, this feature provides you with the ability to avoid the overhead and performance hit associated with attempting to populate the order base line grid and the release instructions with 100s of order line details in scenarios where the goal is to release the remaining quantity for the lines, and perhaps, add some remarks or reference numbers.

By configuring the two properties (below), you can suppress the line details displayed whenever the number of order base lines exceeds the value you set in the (new) maximum number of lines to display property.

Properties:

- The property glog.webserver.rts.hideOBLinesOnMaxCount turns on the functionality. The default value is false, when the property is true the new functionality will be applicable.

- The property glog.webserver.rts.maxNumberOfOBLinesToDisplay sets the maximum number of lines that will be displayed in the order base line grid and the release instructions.

Given the two properties set as glog.webserver.rts.hideOBLinesOnMaxCount=true and glog.webserver.rts.maxNumberOfOBLinesToDisplay=100. When the Ready To Ship action is run against an order base with more than 100 order base lines, the order base lines grid and the release instruction will not be displayed in UI. With this setup, there is no option provided to change the individual lines - the remaining count, source_location, dest_location,dates - will be defaulted in backend. This setup assumes - when the order base line count is greater than 100 - that releasing all the remaining amounts is the desired outcome. You will still be able to enter the order release reference number and remarks as part of the releasing process.

Different Options:

- Property glog.webserver.rts.hideOBLinesOnMaxCount=false - Current behavior, any value of order base lines will be to be displayed - subject to the challenges related to attempting to display more than 999 lines.

- Property glog.webserver.rts.hideOBLinesOnMaxCount=true and property glog.webserver.rts.maxNumberOfOBLinesToDisplay=100 and the number of order base lines selected is less than 100, the order base line will be displayed.

-

Property glog.webserver.rts.hideOBLinesOnMaxCount=true and property glog.webserver.rts.maxNumberOfOBLinesToDisplay=100 and the number of order base lines selected is greater than 100, the order base line will be not be displayed and the assumption is that the user wants to release the remaining amounts.

Provides you with an option for processing more than 999 order base lines as part of you Ready To Ship process.

Steps to Enable

Set the two properties as desired for your implementation.

- The property glog.webserver.rts.hideOBLinesOnMaxCount turns on the functionality. The default value is false, when the property is true the new functionality will be applicable.

- The property glog.webserver.rts.maxNumberOfOBLinesToDisplay sets the maximum number of lines that will be displayed in the order base line grid and the release instructions.

Tips And Considerations

Attempting to run the Ready To Ship action on more than 999 order base lines will cause the system to error out.

Multi-Select View Related Order Releases Action on Buy Shipments

With this feature you now have the ability to easily find all the order releases related to a set of shipments. This is made possible by a new multi-select Shipment View Action - View Related Order Releases, that allows you to select multiple Buy Shipments and then run the View Related Order Releases action to see all the order releases related to the selected set of Buy Shipments. The order release finder result that is returned by this action provides you will all the normal Order Release actions, so you are able to move orders, unschedule orders etc.

To use the feature - simply select one or more Buy Shipments that you are interested in and run the Shipment View Action - View Related Order Releases.

Select a Set of Buy Shipments

Then run the action - Shipment Management > Shipment Management > Buy Shipments > Actions.> Shipment Management > View > Related Order Releases.

Run Action - View Related Order Releases

The result from the action is an Order Release Finder Result with the set or Order Releases from the select set of buy shipments. Since this is a Finder Result - you have the option to configure the results so that the columns included and the order of the columns support your requirements.

View Related Order Releases - Order Release Finder Result

Provides the planner with an easy way to view all the related order release for a set of Buy Shipments.

Steps to Enable

You don't need to do anything to enable this feature.

Include TiHi THUs on Packaged Item in THU Profile

This feature provides you with a new parameter that will allow OTM to Include the TiHi THUs On Packaged Item In the THU Profile. When the property is set to TRUE, OTM will dynamically include the TiHi THUs in the THU profile when building ship units.

The new parameter is found in Shipment Management > Power Data > General > Logic Configuration>logic configuration type of SUBLD LOGIC PARAMETER. The parameter INCLUDE TIHI THUS ON PACKAGE ITEM IN THU PROFILE has a default value of FALSE - for backward compatibility. To take advantage of this new capability the parameter value should be set to TRUE.

INCLUDE TIHI THUS ON PACKAGE ITEM IN THU PROFILE Parameter

In the example below, with INCLUDE TIHI THUS ON PACKAGE ITEM IN THU PROFILE set to TRUE – the TiHi THUs included with the THU Profile will be used.

Union of the TiHi Transportation Handling Unit(s) and THU Profile Will be Used

This feature eliminates the requirement to update the THU profile on your Package Item to include the THU specified on the information defined in your TiHi data. With this parameter set to TRUE - OTM will accept the information provided on the TiHi as valid without forcing you to update the THU profile on the Packaged Item related to the TiHi.

Steps to Enable

You don't need to do anything to enable this feature.

Property to Turn Off Logic Setting Order Release Item Out of Date Status

This feature provides you with a new parameter that you can use to turn off (or on) the Order Release Item Out Of Date Status check which involves checking the effective/expiration date of the item on your order line against your order's early pickup date. When the new property glog.order.newOrderReleaseLine.checkItemEffectiveDates is On (the check is off by default), a check is done to determine if the order release early pickup date is outside of the item's effective/expiration date, if it is outside the range then the order planning status type of PLANNING will be set to the status value of ITEM OUT OF DATE.

In the setup below, if the property glog.order.newOrderReleaseLine.checkItemEffectiveDates were On, the Order Release's PLANNING status value would be set to ITEM OUT OF DATE, since the Early Pickup Date on the order June 8th 2021, is outside of the Effective/Expiration date range on the Item - March 1st to May 31st.

Item with Effective/Expiration Set

Order Release with Early Pickup Date Outside of Item Effective/Expiration Range

Provides the option to turn-off unnecessary effective date checking logic, which provides the opportunity to improve performance.

Steps to Enable

You don't need to do anything to enable this feature.

Property to Turn Off Logic Setting Order Release Known Shipper Value from Order Base

This feature provides you with a new property, glog.order.setIsKnownShipperFromOrderBase that allows you to turn off the logic that sets the Known Shipper value on your Order Release from the Order Base.

The Known Shipper/Unknown Shipper settings are used inside the planning logic to identify the Air Schedules that can be used in planning - Known Shippers are assumed to be those shippers who have provided the appropriate paperwork so that both Cargo Only Flights and mixed Cargo and Passenger Flights are allowed. Unknown Shippers will only be scheduled on Cargo Only Flights.

If you do not plan with Air Schedules - you can turn off the process that sets the Known Shipper from the Order Base.

For backward compatibility the glog.order.setIsKnownShipperFromOrderBase property is set to TRUE by default.

We recommend setting the property value to FALSE in all implementations where this logic is unnecessary.

Air Schedule - Cargo Only (Checked) or Passenger and Cargo Flight (Unchecked)

Known Shipper Flag on Order Base - Checked = Known Shipper Unchecked - UnKnown Shipper

This feature provides you with the opportunity to, potentially, improve system performance, by skipping an unnecessary Known Shipper override.

Steps to Enable

To enable this new behavior you will need to set the property glog.order.setIsKnownShipperFromOrderBase to false.

Navigate to Configuration and Administration > Property Management > Property Sets.

NOTE: Only the DBA.ADMIN user can access and use the Property Sets page.

Tips And Considerations

We encourage setting the property glog.order.setIsKnownShipperFromOrderBase to FALSE if this check is not part of your process.

Add Ship Unit Content to Order Movement XML

This feature provides the option to include the Ship Unit Content (Line) data to the Order Movement outbound XML when your Out XML profile includes the required Xpath.

Xpath: OrderMovement/OrderMovementD/ShipUnit/ShipUnitContent/*

Provides access to the Ship Unit Content within the Order Movement outbound XML.

Steps to Enable

If you wanted to include the non-required element of Ship Unit Content for your Order Movements, you would enter "OrderMovement/OrderMovementD/ShipUnit/ShipUnitContent/*" in the Included Xpath field.

This page is accessed via Business Process Automation > Power Data > Integration > Out XML Profiles.

NOTE: Some understanding of the Oracle Transportation Management XML schema is required to effectively use this functionality.

Equipment Reference Unit Rounding Threshold and Rounding Grouping Level

This feature provides you with the ability to configure your Equipment Reference Units (ERUs) so that fractional ERU amounts are rounded up or down according to your ERU usage requirements. The Rounding Threshold value on the ERU allows you to set the decimal value that will be used to determine if the ERU count will be rounded up or rounded down. The Rounding Grouping Level allows you to determine which grouping level will be evaluated - either Order, Location or Order Plan To.

ERU Rounding Threshold and Rounding Grouping Level

The Rounding Threshold value - practically speaking - a value > 0 but < 1, is interpreted such that any fractional value for a grouped ERU total that is less than or equal to the threshold value will be rounded down, any fractional value greater than the threshold value will be rounded up.

Assuming a Rounding Threshold of .2, the table below shows the different rounding results to expect.

| Cumulative ERU Value | Rounded ERU Value |

|---|---|

| 10.1 | 10 |

| 12.2 | 12 |

| 14.3 | 15 |

| 15.9 | 16 |

The Rounding Grouping Levels - Order, Location or Order Plan To - provide you with different options for grouping and totaling the ERU values that will then be used for rounding.

ERU Rounding Grouping Levels

When you select the Rounding Group Level of Order, each order is a group - so rounding is evaluated at the stop level on an order-by-order basis. Using the Order Rounding Group Level, the ERU values on the order lines for each order are summed and then the ERU value is rounded up or down depending. This setup is intended to support the scenario where you want to receive, manage and calculate pallet spaces at the order level. In the example below, the result is two ship units (rounded up to 34, in this case) for the stop.

| Order ID | Source | Destination | ERU Value | Rounded ERU Value |

|---|---|---|---|---|

| Order ABC | DC1 | 1001 | 10.4 | 11 |

| Order XYZ | DC1 | 1001 | 22.5 | 23 |

| ERU Rounded by Order | 32.9 | 34 |

When you select the Rounding Group Level of Location, the grouping is defined by the ERU Grouping value entered on your locations. The location ERU Grouping value comes from the Order Ship To Location. The ERU Grouping on your Location(s) provides you with additional flexibility for defining how OTM calculates the number of ERUs (pallets/pallet spaces) going to a location or location grouping.

Rounding Group Level - Location ERU Group

The two examples below - the mall delivery case and the cross dock case - are two examples where the Location Rounding Grouping Level option and the ERU Grouping value could be used.

Case 1 – The mall delivery case – in this case the goal is to have the ERU calculation done at a higher level than the actual order plan to location - the goal is to have the ERU calculation done considering all the locations having the same ERU Grouping ID. In the example below, all the locations have the same Location Group ID - Mall 1 - the ERU calculation and rounding will be done for the total for all the locations with the same ERU Group ID. In this case, the total across all the locations with the Mall 1 ERU Grouping ID = 6.2 and with a Rounding Threshold of .2 this value will be rounded down to 6 ERUs/pallet spaces. Had the calculation been done on an order-by-order basis the number of ERUs would have been calculated as 8 ERUs/pallet spaces.

Location Rounding Grouping Level - Mall Delivery Case

Case 2 – Cross dock case – in this case you want the grouping for ERU calculation to be done by the looking at the order ship to location ERU Group ID to determine how to build the ERUs/pallet spaces. In this scenario - where an intermediate point/cross dock is involved - the requirement is to calculate ERUs assuming the intermediate will not break apart the ERUs/pallets. In this case, Location ERU Grouping ID can be set to the location id - with this setup OTM will look to the order ship to location ERU Grouping to determine how to build pallets, and this calculation will be used even for the pickup to the cross dock portion of the solution as well as the cross dock to order ship to location.

Location Rounding Grouping Level - Cross Dock Case

With this setup, each ship to or plan to is evaluated to determine the ERUs/pallet spaces. A shipment with 10 stops all with a value of.3 ERUs will be rounded up so that each stop consumes a full pallet space in the truck.

If an order comes in with the plan to set to an intermediate point (like a cross dock) with a different ship to location. When rounding to the order plan to location OTM will group all orders going to this location on the shipment together to build pallet spaces. In the example where there is a pickup and drop off at intermediate point 1 and another drop off at intermediate point 2 – all the orders going to intermediate point 1 can be considered together and all the orders to intermediate point 2 can be considered together when counting full pallet spaces

You will find this feature to be extremely beneficial for calculating the correct number of pallets and pallet spaces required in implementations where ERUs are used to model pallets and pallet spaces.

Steps to Enable

To take advantage of this feature - you will need to either create or modify your existing ERU configurations and provide the desired values for:

- The Rounding Threshold (between 0 and 1). Values less or equal to the threshold will be rounded down.

- Rounding Grouping Level either Order, Location or Plan To.

Tips And Considerations

NOTE: ERU rounding is not implemented for Consol Shipment (Ocean FCL).

Enhanced and Extended Set of Flex Field Related Rate Basis Items

This feature provides you with an enhanced and extended set of Flex Field related Rate Basis Items (RBIs) that you can use in defining your Flex Field related rates. Where an older "equivalent" Flex Field RBI exists (from the 6.4.2 release), we recommend that you move from the older 6.4.2 version of the Flex Field RBI to the new and improved version.

In the example below - note that the new approach for defining the Flex Field RBIs have both the Qualifier (User Defined Attribute) and the Value defined together on a single line. This new formulation provides a clear association of the condition, attribute and value.

RBI Flex Field Example Order String Flex Field

Below is the list of new Flex Field RBIs provided in 21C. Note the addition of new RBIs for Line Item, Order Line Item and Ship Unit Line Item.

| New 21C Flex Field RBIs | Type | Description | |

|---|---|---|---|

| Line Item String Flex Field | Specifies the Rate Basis Item corresponding to line item string flex field. The value provided in the flex filed is considered as string. | ||

| Line Item String Flex Field as Distance | Specifies the Rate Basis Item corresponding to line item string flex field as distance. The value provided in the flex filed is considered as distance. | ||

| Line Item String Flex Field as Duration | Specifies the Rate Basis Item corresponding to line item string flex field as duration. The value provided in the flex filed is considered as duration. | ||

| Line Item String Flex Field as Currency | Specifies the Rate Basis Item corresponding to line item string flex field as currency. The value provided in the flex filed is considered as currency. | ||

| Line Item String Flex Field as a Number | Specifies the Rate Basis Item corresponding to line item string flex field as number. | ||

| Line Item String Flex Field as Weight | Specifies the Rate Basis Item corresponding to line item string flex field as weight. The value provided in the flex filed is considered as weight. | ||

| Line Item String Flex Field as Volume | Specifies the Rate Basis Item corresponding to line item string flex field as volume. The value provided in the flex filed is considered as volume. | ||

| Line Item String Flex Field as Date | Specifies the Rate Basis Item corresponding to line item string flex field as date. The value provided in the flex filed is considered as date. | ||

| Line Item Number Flex Field | Specifies the Rate Basis Item corresponding to line item number flex field. | ||

| Line Item Number Flex Field as Distance | Specifies the Rate Basis Item corresponding to line item number flex field as distance. The value provided in the flex filed is considered as distance. | ||

| Line Item Number Flex Field as Duration | Specifies the Rate Basis Item corresponding to line item number flex field as duration. The value provided in the flex filed is considered as duration. | ||

| Line Item Number Flex Field as Currency | Specifies the Rate Basis Item corresponding to line item number flex field as currency. The value provided in the flex filed is considered as currency. | ||

| Line Item Number Flex Field as Weight | Specifies the Rate Basis Item corresponding to line item number flex field as distance. The value provided in the flex filed is considered as distance. | ||

| Line Item Number Flex Field as Volume | Specifies the Rate Basis Item corresponding to line item number flex field as volume. The value provided in the flex filed is considered as volume. | ||

| Line Item Date Flex Field | Specifies the Rate Basis Item corresponding to line item date flex field. The value provided in the flex filed is considered as date. | ||

| Order Currency Flex Field | Both | Specifies the Rate Basis Item corresponding to order currency flex field. The value provided in the flex filed is considered as currency. | |

| Order Date Flex Field | Conditional | Specifies the Rate Basis Item corresponding to order date flex field. | |

| Order Line Item String Flex Field | Both | Specifies the Rate Basis Item corresponding to order line item string flex field. The value provided in the flex filed is considered as string. | |

| Order Line Item String Flex Field as Distance | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as distance. The value provided in the flex filed is considered as distance. | |

| Order Line Item String Flex Field as Duration | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as duration. The value provided in the flex filed is considered as duration. | |

| Order Line Item String Flex Field as Currency | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as currency. The value provided in the flex filed is considered as currency. | |

| Order Line Item String Flex Field as a Number | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as number. The value provided in the flex filed is considered as number. | |

| Order Line Item String Flex Field as Weight | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as weight. The value provided in the flex filed is considered as weight. | |

| Order Line Item String Flex Field as Volume | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as volume. The value provided in the flex filed is considered as volume. | |

| Order Line Item String Flex Field as Date | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as date. The value provided in the flex filed is considered as date. | |

| Order Line Item Number Flex Field | Both | Specifies the Rate Basis Item corresponding to order line item string flex field as date. The value provided in the flex filed is considered as date. | |

| Order Line Item Number Flex Field as Distance | Both | Specifies the Rate Basis Item corresponding to order line item number flex field as distance. The value provided in the flex filed is considered as distance. | |

| Order Line Item Number Flex Field Duration | Both | Specifies the Rate Basis Item corresponding to order line item number flex field as duration. The value provided in the flex filed is considered as duration. | |

| Order Line Item Number Flex Field as Currency | Both | Specifies the Rate Basis Item corresponding to order line item number flex field as currency. The value provided in the flex filed is considered as currency. | |

| Order Line Item Number Flex Field as Weight | Both | Specifies the Rate Basis Item corresponding to order line item number flex field as weight. The value provided in the flex filed is considered as weight. | |

| Order Line Item Number Flex Field as Volume | Both | Specifies the Rate Basis Item corresponding to order line item number flex field as volume. The value provided in the flex filed is considered as volume. | |

| Order Line Item Date Flex Field | Both | Specifies the Rate Basis Item corresponding to order line item date flex field. The value provided in the flex filed is considered as date | |

| Order Number Flex Field | Both | Specifies the Rate Basis Item corresponding to order number flex field. | |

| Order Number Flex Field as Currency | Both | Specifies the Rate Basis Item corresponding to order number flex field as currency. The value provided in the flex filed is considered as currency. You must make sure that the number flex field value is provided along with the unit of currency such as EUR, USD, etc. otherwise the default unit is considered. | |

| Order Number Flex Field as Duration | Both | Specifies the Rate Basis Item corresponding to order number flex field as duration. The value provided in the flex filed is considered as duration. You must make sure that the number flex field value is provided along with the unit of duration such as D/H/M otherwise the default unit is considered. | |

| Order Number Flex Field as Volume | Both | Specifies the Rate Basis Item corresponding to order number flex field as volume. The value provided in the flex filed is considered as volume. You must make sure that the number flex field value is provided along with the unit of volume such as GAL, CAN GAL, etc. otherwise the default unit is considered. | |

| Order Number Flex Field as Weight | Both | Specifies the Rate Basis Item corresponding to order number flex field as weight. The value provided in the flex filed is considered as weight. You must make sure that the number flex field value is provided along with the unit of weight such as LB, KG, etc. otherwise the default unit is considered. | |

| Order String Flex Field | Both | Specifies the Rate Basis Item corresponding to order string flex field. The value provided in the flex filed is considered as string. | |

| Order String Flex Field as Currency | Both | Specifies the Rate Basis Item corresponding to order string flex field as currency. The value provided in the flex filed is considered as currency. You must make sure that the string flex field value is provided along with the unit of currency such as EUR, USD, etc. otherwise the default unit is considered. | |

| Order String Flex Field as Date | Conditional | Specifies the Rate Basis Item corresponding to order string flex field as date. The value provided in the flex filed is considered as date. When you select this RBI, a Qualifier drop-down list will be available. | |

| Order String Flex Field as Distance | Both | Specifies the Rate Basis Item corresponding to order string flex field as distance. The value provided in the flex filed is considered as distance. You must make sure that the string flex field is provided along with the unit of distance such as MI, KM, etc. otherwise the default unit is considered. | |

| Order String Flex Field as Duration | Both | Specifies the Rate Basis Item corresponding to order number flex field as duration. The value provided in the flex filed is considered as duration. You must make sure that the number flex field value is provided along with the unit of duration such as D/H/M otherwise the default unit is considered. | |

| Order String Flex Field as Volume | Both | Specifies the Rate Basis Item corresponding to order string flex field as volume. The value provided in the flex filed is considered as volume. You must make sure that the string flex field value is provided along with the unit of volume such as GAL, CAN GAL, etc. otherwise the default unit is considered. | |

| Order String Flex Field as Weight | Both | Specifies the Rate Basis Item corresponding to order string flex field as weight. The value provided in the flex filed is considered as weight. You must make sure that the string flex field value is provided along with the unit of weight such as LB, KG, etc. otherwise the default unit is considered. | |

| Shipment Currency Flex Field | Both | Specifies the Rate Basis Item corresponding to shipment currency flex field. | |

| Shipment Date Flex Field | Conditional | Specifies the Rate Basis Item corresponding to shipment date flex field. | |

| Shipment Number Flex Field | Both | Specifies the Rate Basis Item corresponding to shipment string flex field as date. The value provided in the flex field is considered as date. | |

| Shipment Number Flex Field as Currency | Both | Specifies the Rate Basis Item corresponding to shipment number flex field as currency. The value provided in the flex field is considered as currency. Make sure that you provide the number flex field value along with the unit of currency such as EUR, USD, etc. otherwise the default unit is considered. | |

| Shipment Number Flex Field as Distance | Both | Specifies the Rate Basis Item corresponding to shipment number flex field as distance. The value provided in the flex field is considered as distance. Make sure that you provide the number flex field value along with the unit of distance such as MI, KM, etc. otherwise the default unit is considered. | |

| Shipment Number Flex Field as Duration | Both | Specifies the Rate Basis Item corresponding to shipment number flex field as duration. The value provided in the flex field is considered as duration. Make sure that you provide the number flex field value along with the unit of duration such as D/H/M otherwise the default unit is considered. | |

| Shipment Number Flex Field as Volume | Both | Specifies the Rate Basis Item corresponding to shipment number flex field as volume. The value provided in the flex field is considered as volume. Make sure that you provide the number flex field value along with the unit of volume such as GAL, CAN GAL, etc. otherwise the default unit is considered. | |

| Shipment Number Flex Field as Weight | Both | Specifies the Rate Basis Item corresponding to shipment number flex field as weight. The value provided in the flex field is considered as weight. Make sure that you provide the number flex field value along with the unit of weight such as LB, KG, etc. otherwise the default unit is considered. | |

| Shipment Stop Date Flex Field | Conditional | Specifies the Rate Basis Item corresponding to shipment stop date flex field. | |

| Ship Unit Line Item String Flex Field | Specifies the Rate Basis Item corresponding to ship unit line item string flex field. The value provided in the flex filed is considered as string. | ||

| Ship Unit Line Item String Flex Field as Distance | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as distance. The value provided in the flex filed is considered as distance. | ||

| Ship Unit Line Item String Flex Field as Duration | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as duration. The value provided in the flex filed is considered as duration. | ||

| Ship Unit Line Item String Flex Field as Currency | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as currency. The value provided in the flex filed is considered as currency. | ||

| Ship Unit Line Item String Flex Field as a Number | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as number. The value provided in the flex filed is considered as number. | ||

| Ship Unit Line Item String Flex Field as Weight | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as weight. The value provided in the flex filed is considered as weight. | ||

| Ship Unit Line Item String Flex Field as Volume | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as volume. The value provided in the flex filed is considered as volume. | ||

| Ship Unit Line Item String Flex Field as Date | Specifies the Rate Basis Item corresponding to ship unit line item string flex field as date. The value provided in the flex filed is considered as date. | ||

| Ship Unit Line Item Number Flex Field | Specifies the Rate Basis Item corresponding to ship unit line item number flex field. | ||

| Ship Unit Line Item Number Flex Field as Distance | Specifies the Rate Basis Item corresponding to ship unit line item number flex field as distance. The value provided in the flex filed is considered as distance. | ||

| Ship Unit Line Item Number Flex Field as Duration | Specifies the Rate Basis Item corresponding to ship unit line item number flex field as duration. The value provided in the flex filed is considered as duration. | ||

| Ship Unit Line Item Number Flex Field as Currency | Specifies the Rate Basis Item corresponding to ship unit line item number flex field as currency. The value provided in the flex filed is considered as currency. | ||

| Ship Unit Line Item Number Flex Field as Weight | Specifies the Rate Basis Item corresponding to ship unit line item number flex field as weight. The value provided in the flex filed is considered as weight. | ||

| Ship Unit Line Item Number Flex Field as Volume | Specifies the Rate Basis Item corresponding to ship unit line item number flex field as volume. The value provided in the flex filed is considered as volume. | ||