- Revision History

- Overview

- Feature Summary

- Warehouse Management

-

- WMS Common

-

- Infer UOM from Alternate Item Barcode

- Associate SAAS Application Configuration with Oracle Content Management (OCM/OCE) Configuration Detail

- Extend Support for Additional Tables for Purge Handling

- Extend Support for Additional Screens in Configuration Export/Import Tool

- Web UI Improvements

- Support for Swedish Translations

-

- Inbound Logistics

- Inventory Operations

-

- Generate Inventory Balance Snapshots by ERP Bucket

- Support Cycle Counting the Same Item in Different UOMs for the Same LPN/Location

- Perform Create LPN in Cases and Packs

- Perform Non-Tasked Cycle Counting for a Specific Item in Deferred Mode

- Auto Removal of Inherited Lock Code on LPN When Transferring from a Location

- Add Velocity Code to Facility-Level Item Definition

-

- Outbound Logistics

-

- Improvements to Planned Load Interface for Action Code at the Order Level

- Support System Driven Alternate Location During Picking

- Extend Post Packing Transaction to Support Load Assignment, Manifesting and Pallet Handling

- Support FEFO for Multi-Item LPN Allocation

- Initiate Loading Based on Trailer Scan

-

- Warehouse Workforce Management

- WMS Mobile App

- Cloud SCM Integration

-

- Predefined Integration Mappings from Inventory Management for Manufacturing and Maintenance Work Order Picking Request

- Predefined Integration Mappings to Inventory Management for Manufacturing and Maintenance Work Order Picking Confirmations

- Predefined Integration Mappings to Inventory Management for Manufacturing and Maintenance Work Order Picking Cancellations

- Predefined Integration Mappings to Transportation Management for Order Line Split Across Different Planned Loads

-

- WMS Common

Update 23D

Revision History

This document will continue to evolve as existing sections change and new information is added. All updates appear in the following table:

| Date | Module | Feature | Notes |

|---|---|---|---|

| 09 FEB 2024 | WMS Common |

Updated document. Revised feature information. |

|

| 01 FEB 2024 | Outbound Logistics | Extend Post Packing Transaction to Support Load Assignment, Manifesting and Pallet Handling | Updated document. Revised feature information. |

| 15 DEC 2023 | WMS Common | Updated document. Revised feature information. |

|

| 15 DEC 2023 |

WMS Common |

Updated document. Revised feature information. |

|

| 15 DEC 2023 |

Inbound Logistics | Support Receiving the Same Item in Different UOMs for the Same LPN |

Updated document. Revised feature information. |

| 15 DEC 2023 |

Inbound Logistics | Updated document. Revised feature information. |

|

| 15 DEC 2023 |

Inventory Operations | Updated document. Revised feature information. |

|

| 15 DEC 2023 |

Inventory Operations |

Support Cycle Counting the Same Item in Different UOMs for the Same LPN/Location |

Updated document. Revised feature information. |

| 15 DEC 2023 |

Inventory Operations |

Auto Removal of Inherited Lock Code on LPN When Transferring from a Location |

Updated document. Revised feature information. |

| 15 DEC 2023 |

Inventory Operations |

Perform Non-Tasked Cycle Counting for a Specific Item in Deferred Mode |

Updated document. Revised feature information. |

| 14 NOV 2023 | WMS Common | Updated document. Revised feature information. |

|

| 13 OCT 2023 | Created initial document. |

Overview

HAVE AN IDEA?

HAVE AN IDEA?

We’re here and we’re listening. If you have a suggestion on how to make our cloud services even better then go ahead and tell us. There are several ways to submit your ideas, for example, through the Ideas Lab on Oracle Customer Connect. Wherever you see this icon after the feature name it means we delivered one of your ideas.

GIVE US FEEDBACK

We welcome your comments and suggestions to improve the content. Please send us your feedback at oracle_fusion_applications_help_ww_grp@oracle.com.

DISCLAIMER

The information contained in this document may include statements about Oracle’s product development plans. Many factors can materially affect Oracle’s product development plans and the nature and timing of future product releases. Accordingly, this Information is provided to you solely for information only, is not a commitment to deliver any material, code, or functionality, and should not be relied upon in making purchasing decisions. The development, release, and timing of any features or functionality described remains at the sole discretion of Oracle.

This information may not be incorporated into any contractual agreement with Oracle or its subsidiaries or affiliates. Oracle specifically disclaims any liability with respect to this information. Refer to the Legal Notices and Terms of Use for further information.

Feature Summary

Column Definitions:

Report = New or modified, Oracle-delivered, ready to run reports.

UI or Process-Based: Small Scale = These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

UI or Process-Based: Larger Scale* = These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

Features Delivered Disabled = Action is needed BEFORE these features can be used by END USERS. These features are delivered disabled and you choose if and when to enable them. For example, a) new or expanded BI subject areas need to first be incorporated into reports, b) Integration is required to utilize new web services, or c) features must be assigned to user roles before they can be accessed.

Warehouse Management

WMS Common

Infer UOM from Alternate Item Barcode

An item in the warehouse may have one or multiple item barcode associated to it. Earlier, on scanning the alternate barcode and performing receiving, putaway, picking or cycle counting, WMS considered the item code and populated on the RF screen when the transaction was executed, while the system did not complete utilize the "qty per UOM" and "UOM" field from the item barcode entity. In cases where different customer/vendors may track item/inventory and define their package barcode at sku level, pack level, and case level. For example, Customer-1 has configured barcodes for a set of 12 and 8 Blue pens, and the UOM for these blue pens are tracked in terms of Cases. Here, the conversion factor is tracked in terms of 12 and 8 quantities. Considering this factor, when a vendors send the item barcode for Case of 12 and Case of 8, the warehouse operations must be equipped to identify the “UOM” and “quantity per UOM” of the Sku on scanning the barcode that the vendor has sent.

In 23D, WMS is enhanced now to utilize the “UOM” and “quantity per UOM” fields on the Item Barcode entity allowing you to determine the SKU by inferring the UOM from the item barcode scanned. The main objective of having the “quantity per UOM” auto-populated at scanning is to gain efficiency when managing products with multiple UOMs.

A new screen parameter option “Infer UOM from Item Barcode" is introduced to “qty-uom” parameter. This new screen parameter is added to the following RF screens:

- RF Recv {lpn} Load (rf.inbound.cwrfrecvlpnload) and Recv {lpn} Shipment (rf.inbound.cwrfrecvlpnshpmt)

- RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn)

- RF Create LPN (rf.inbound.cwrfcreatelpn)

- RF Pack NC Active {order} (rf.outbound.cwrfpackncactiveorder)

RECEIVING SKU WITH INFER UOM FROM ITEM BARCODE

On enabling the Infer UOM from the item barcode screen parameter, the RF Receiving module is enhanced to pick the UOM on scanning the item barcode. On scanning the item barcode, you can now directly receive items to your warehouse in one go.

Before 23D, on scanning the item barcode to receive the SKU, the system picked the “UOM” and “quantity per UOM” from the item master. To change the UOM or quantity per UOM, you had to invoke the CTRL-K to switch UOM and proceed receiving in Multiple UOMs and CTRL-Q hotkey to Change Case/Pack qty.

In 23D, you can simplify your inbound operations by configuring the screen parameter “qty-uom” to “infer UOM from item barcode” and scan the item barcode when dealing in terms of Packs and Cases with variation in Package UOM.

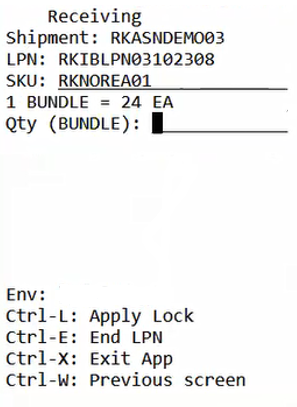

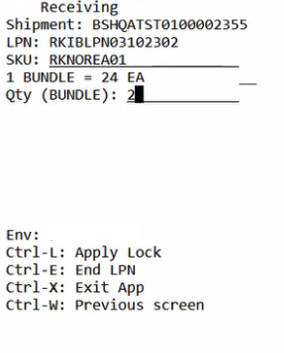

- On scanning the barcode corresponding to a record in the item barcode entity, the system picks the UOM and Qty per UOM, and defaults the value in the quantity per UoM field. i.e., here, the scanned item has the primary UOM of units, and scanned barcode has the Case UOM of Bundle with Qty per UOM of 24. Therefore, the sku-qty entry screen displays 1 Bundle =24 Eaches.

Inferring UOM from Item Barcode during Receiving

NOTE: If you are dealing with items whose primary UOM is grams and the scanned barcode corresponds to Kilograms, then the system picks up UOM from the item barcode scanned.

- The system defaults item’s Std_pack or Std_case qty conversion when the item barcode scanned does not have UOM configured.

- If you receive an item in Infer mode, on scanning only the Case barcode, the pack_qty on the inventory will be 0. Similarly, if only the Pack barcode is scanned, the case_qty on the inventory will be 0.

CYCLE COUNT WITH INFER UOM FROM ITEM BARCODE

Items in your warehouse may be stored in different UOMs of the same UOM class for ease of inbound/outbound operations. So, when performing a cycle count to guarantee inventory accuracy, it would be more convenient if it could be done in the same UOM as how it is stored. Therefore, we have enhanced the RF cycle count module to pick inventories from reserve or active locations in terms of case_uom and packs_uom by scanning the item barcode.

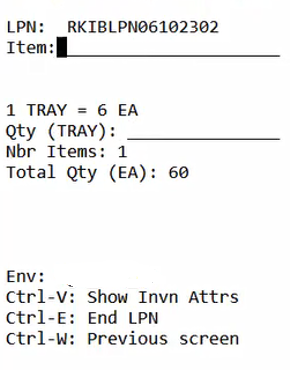

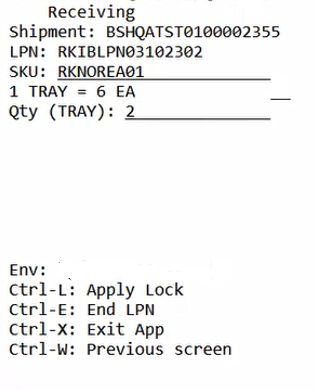

- On scanning the barcode corresponding to a record in the item barcode entity, the system picks the UOM and Qty per UOM, and defaults the value in the quantity per UoM field. i.e., if the scanned item has primary UOM of eaches and scanned barcode has Pack UOM of Tray with Qty per UOM of 6. Therefore, the sku-qty entry screen displays 1 Tray = 6 Eaches.

- In 23D, we have expanded the Infer UOM from item barcode functionality to support RF Cycle Counting in SKU scan mode.

NOTE: On scanning each SKU in SKU Scan Mode, the system increments the qty of the count by 1 UOM of the item barcode. If the SKU scanned is in quantity entry mode, the UOM switches as per the UOM from item barcode.

- WMS Activity & IHTs with REF field values(Ref_Code_13, Ref_Value_13, Ref_Code_14, and Ref_Value_14) are updated as per the counted UOM's.

For more information on Cycle counting in Multiple UOM, refer to Support Cycle Counting the Same Item in Different UOMs for the LPN/Location.

CREATE LPN WITH INFER UOM FROM ITEM BARCODE

As part of 23D Infer UoM enhancements, WMS has also enhanced RF Create LPN and RF Create LPN from Active module to pick inventories in terms of case_uom and pack_uom by scanning the item barcode.

RF CREATE LPN

- If the scanned barcode corresponds to item barcode entity, then the system picks the UOM, and quantity per UOM, and defaults the same in the Quantity entry field.

- You can scan item barcodes corresponding to Cases UOM and separate item barcodes corresponding to Pack UOM in the same LPN.

On scanning the item barcode corresponding to case, the system picks the case_qty from item barcode entity. You can continue to scan a different UOM for the same LPN.

Inferring UOM from Item Barcode during create LPN

NOTE: We recommend that you avoid creating LPN if different variations of Case Qty for the same item are used for creating inventory. Similarly, prevent creating LPN if different variations of Pack Qty for the same item are used for creating inventory. While creating inventory, avoid creating LPN if Case Qty is not an integral multiple of Pack Qty.

- You can transact in terms of primary_uom if you scan a barcode which is not configured in the item barcode.

- You now can perform Create LPN for an item that has Multiple UOM's presents in the location.

- In 23D, we have relaxed the restriction where the system displays an error “multiple UOM cannot be counted for same SKU” and allows you to scan the item barcode corresponding to Case and Pack for the same LPN.

NOTE: On scanning an item corresponding to the Case barcode and then the Pack barcode for the same LPN, the pack_qty must be an integral multiple of the Case_qty scanned. Otherwise, the system displays an [Pack UOM] needs to be an integral multiple of [Case UOM]” error.

RF CREATE LPN FROM ACTIVE

You can create a LPN from an active location. We have enhanced this module to infer UOM from item barcode. You can perform RF Create LPN from Active with Infer mode by disabling the parameter “active-locn-lpn-create” mode or set to No/blank.

NOTE: If the parameter is set to by sku or all sku, the infer UOM functionality will not work. And, when transacting from RF create lpn from active, the case_qty and pack_qty will be 0 in active location.

- On scanning the active location and item barcode, the system picks the UOM, quantity per UOM, and updates total qty on the inventory.

NOTE: When performing RF Create LPN from Active, the system picks the pack_qty and case_qty from the item barcode. However, if item barcode with is not part of item barcode entity, then system picks the qty from item_master.

- When creating LPN from active location, on scanning the different item barcode, the active inventory picks from vendors item barcode.

- The case_qty and pack_qty will reflect whatever qty per UOM is mentioned on the vendor’s item barcode.

NOTE: The pack and case qty will not be picked from item-master when doing create lpns from active on scanning vendor item barcode.

- On scanning the item corresponding to the pack barcode which is an integral multiple of case_qty, the system picks the packs_qty and case_qty from the vendor item's barcode, updates the inventory, and the active inventory displays the pack_qty and case_qty from item master. If the pack_qty is not an integral multiple of the Case_qty scanned, the system displays an [Pack UOM] needs to be an integral multiple of [Case UOM]” error.

- If there are instances of scanning the same UOM for the same SKU with different qty per UOM, then the system displays an error “Multiple Case/Pack quantity combinations are not allowed for the same lpn".

NOTE: Currently, if the case_qty and pack_qty differs for an existing inventory, even if the pack_qty and case_qty are 0, the system displays an error.

PACK NC ACTIVE WITH INFER UOM FROM ITEM BARCODE

When performing an RF Pack NC Active (rf.outbound.cwrfpackncactiveorder) module for reserve or active location, WMS allows you to enter the qty in terms of packs and cases if the underlying item or their corresponding inventory were tracked in packs and cases. Enable this new screen parameter "infer-uom-from-barcode" in the RF Pack NC Active module to pick the UOM from the barcode scanned.

- If the scanned barcode corresponds to the item barcode table, then the system picks the UOM, and quantity per UOM, and defaults the same in the Quantity entry field.

NOTE: During Non-Cubed or Cubed Picking, picking the UOM from the barcode scanned is applicable only when the screen parameter is configured to scan the item barcode. If the item barcode scan is not enabled, then inferring the UOM from the barcode scanned will not be applicable. If the scanned item corresponds to the normal item barcode entry, then the system proceeds with the picking screen displaying the quantity to be picked in terms of allocation UOM.

- If allocation UOM is Units and the scanned item corresponds to an inventory record whose Pack/Case Qty does not match the Qty Per UOM mentioned on the Item Barcode scanned, then display the error "Allocated inventory has Pack/Case Qty different than Item Barcodes Qty Per UOM".

SKU–SCAN MODE

- You can perform picking by inferring the UOM from the barcode scanned when allocation UOM is Units and the scanned barcode corresponding to Packs or Cases is in Sku Scan Mode.

- You perform picking by inferring the UOM from the barcode scanned when allocation UOM is Packs and the scanned barcode corresponds to the UOM of Case in Sku Scan Mode.

NOTE: Each scan would increment the quantity picked based on UOM and conversion from the item barcode.

SKU-QUANTITY MODE

- You can perform picking by inferring the UOM from the barcode scanned when allocation UOM is Units and you can scan the barcode corresponding to Packs or Cases in Sku Qty entry mode.

- You can perform picking by inferring the UOM from the barcode scanned when allocation UOM is Packs and you can scan the barcode corresponding to Case in Sku Qty Mode.

Steps to Enable

For RF Receiving, RF Cycle Count Location, and RF Create LPN:

- Go to RF Recv {lpn} Load (rf.inbound.cwrfrecvlpnload)/Cycle Count Location/Create LPN transaction.

- Click Screen Parameters > qty-uom

- Select the parameter choice Infer UOM from the Item Barcode drop-down menu.

- Click Save.

For RF Pack NC Active:

- Go to RF Pack NC Active {order} (rf.outbound.cwrfpackncactiveorder)

- Click Parameters > infer-uom-from-item-barcode

- Select the parameter choice None|Yes|No.

- Click Save.

Key Resources

Associate SAAS Application Configuration with Oracle Content Management (OCM/OCE) Configuration Detail

We have streamlined the process of managing access permissions for WMS repositories and channels within your OCM instance, making it incredibly easy. We have introduced a new set of enhancements to the SAAS App Configuration screen so that you can manage / update email IDs associated with WMS repositories within Oracle Content Management. Whether you're fine-tuning communication channels or adapting to organizational changes, this feature ensures your OCM configuration within WMS stays up-to-date.

CHANGE EMAIL ID IN SAAS APP CONFIGURATION

When you change the email ID on OCM record within SAAS App Configuration, WMS will automatically handle the access permission on the repositories and channels. The automatic notifications sent from OCM to the respective users eliminates the need for additional notifications from WMS, streamlining the communication process.

If you change the email ID on an OCM record in SAAS App Configuration without changing any other value, here's what will happen to the repositories and channels on your OCM instance:

- Manager access for the previous user defined in App Parm 7 will be revoked.

- Manager access for the new user defined in App Parm 7 will be granted.

- SAAS App Configuartion will be seamlessly updated with the new email ID.

CHANGE OCM VALUES IN SAAS APP CONFIGURATION

Previously, unalterable connection values (including Base URL, and App Parm3 through App Parm6) can now be easily updated to match your requirements. While these configurations may not frequently change, this newfound flexibility empowers you to adapt swiftly when necessary.

If changes are detected in the Base URL during record editing, indicating a shift in the OCM instance, the following actions occur:

- New repositories and channels are created in the updated OCM instance.

- Manager access is granted to the user specified in App Parm 7.

- The details of the new repositories and channels are recorded in WMS.

NOTE: Your existing images and files in the old OCM instance remain intact, however cannot be accessed through WMS anymore.

When IDCS (Identity Cloud Service) values change or any attribute from App Parm 3 through 6 is altered, the system will:

- Attempt to generate a new token using the updated IDCS values.

- Send a verification of connectivity through a “validate user” API interaction.

- Grant manager level access to the new client ID on App Parm 4 for the relevant Repository ID and Channel ID.

- Revoke manager level permissions for the old client ID on App Parm 4, with appropriate messaging in case of issues.

If modifications are made to file attributes, updates are swiftly implemented within the SAAS App Configuration.

User Notifications:

- When editing a non-template record, a confirmation message will be displayed to inform potential consequences related to Base URL and email ID changes. The user can proceed after acknowledging the risks.

- A similar confirmation message will appear, emphasizing the implications of Base URL and email ID changes, along with an alert about the potential time needed for the save process.

NOTE: Updates will be initiated only upon user confirmation. If the user opts to cancel, no modifications will be made, preserving your configurations.

CREATE NON-TEMPLATE SAAS APP CONFIGURATION RECORDS

When you attempt to create a SAAS App Configuration record for any facility/company combination where uploads have already occurred, our product offers optimized solutions.

- WMS will compare the proposed SAAS App Configuration with the template record to identify differences.

- If all values match the template, a confirmation message seeks user verification. Proceeding with save creates a new SAAS App Configuration record dedicated for the facility/company.

- If some values differ from the template, a warning message is displayed, emphasizing potential consequences. User confirmation triggers the following actions:If the Base URL differs, indicating a change in OCM Instance, new Repository and Channel are created in the updated OCM Instance. Manager access is granted, and a new SAAS App Configuration record is created.

- If the Base URL remains the same but IDCS values differ, a token is generated and connectivity validated. A new SAAS App Configuration record is created.

- If the Base URL and IDCS values remain the same but file attributes differ, a new SAAS App Configuration record is created.

- If the Base URL, IDCS values, and file attributes remain the same but the email changes, manager access adjustments are made. A new SAAS App Configuration record is created.

NOTE: Users have the flexibility to cancel the process if needed, with no changes made.

Revoking and granting manager access triggers automatic notifications from OCM to relevant users, eliminating the need for additional WMS notifications.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Extend Support for Additional Tables for Purge Handling

As part of improved purge handling capabilities, we have added the following entry in the below table to be purged based on defined frequency:

| Table |

Timeframe to be purged |

|---|---|

| SERIAL_NBR_HISTORY |

3 years from the current date. |

Serial Number History handles the history of Serial Number being linked, delinked, and shipped from LPNs.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Extend Support for Additional Screens in Configuration Export/Import Tool

We have now added additional screens that can use the Configuration Import/Export Tool beyond the initial release in 23B and 23C.

In the following screens, you can now easily migrate and replicate the UI configurations between facilities, companies, and environments by using this tool.

- ReplenishmentTypeZoneXrefView (Replenishment Type Zone Xref)

- Expiry Date Range screen (Wave Template > “Expiry Date Range” action button)

- InputInterfaceConfigView (Input Interface Config)

- VendorCharacteristicsView (Vendor Characteristics View)

- LabelTemplateView (Label Template View)

- BreaksView (Breaks View - WFM)

- CostCentreView (Cost Centre)

- WorkGroupView (Work Group)

- GroupActivityView (Group Activity)

- WFMWork_AreaView (Work Area)

- TeamsView (Teams View - WFM)

- BonusGroupView (Bonus Group View - WFM)

- BonusBudgetView (Bonus Budget View - WFM)

For more information on Export/Import (config) action button and how to Export or Import Configurations, refer the Configuration Export/Import Tool topic in the 23B – What’s New.

Steps to Enable

- In each of the UI configuration screens, click on the Export/Import (config) action button located on the right corner of the UI.

- You can then access the "export_configuration" and "import_configuration" drop-down options.

NOTE: To use the Configuration Export/Import feature in the relevant screens, you need to add the group permission “ConfigImportExport / Import/Export Configuration”.

Key Resources

Web UI Improvements

Warehouse Management is enhancing search and filter criteria in several screens, providing you with more streamlined operations, reduced search times and fewer errors. This efficiency translates into improved order fulfilment rates and reduced operational costs.

NEW CASE/PACK RELATED QUANTITY FIELDS IN MULTIPLE SCREENS

In this release, we have also introduced the ability to check your inventory in terms of cases and packs across multiple screens, as a part of your routine warehouse operations.

The following table represents the screens and their respective quantity fields for cases and packs:

| SCREEN NAME | FIELD NAME |

|---|---|

| Inbound Shipment Detail screen |

|

| ASN Detail screen |

|

| Purchase Order Detail screen |

|

| Order Detail screen |

|

| Outbound Order Detail screen |

|

| Movement Request Detail screen |

|

NOTE:

- By default, the new quantity fields will not be displayed on the data grid; you will need to add the desired columns.

- The literals for “Shipped Uom Qty” is changed to “Shipped UOM Qty”.

DISPLAY CONFIGURED UOM QUANTITY IN APPOINTMENT LIST UI

As a part of further integration of UOM-related changes in the Web UI, we have enhanced the Appointment List screen to display your configured UOM.

Now, in the Appointment List screen, Inbound Shipment Count, Received LPN Count, Number Items and Number LPNs pages will display appended UOM IDs for the quantity fields in the relevant columns. The appended UOM ID is based on what you’ve configured as the Item Primary UOM or as the Facility’s Item Primary UOM.

The following columns will now display the quantity fields by appending its configured UOM ID for the respective pages:

| PAGES | Inbound Shipment Count / Number Items |

Received LPN Count / Number LPNs |

|---|---|---|

| QUANTITY FIELDS WITH APPENDED UOMS | Shipped Quantity | Current Quantity |

| Received Quantity | Original Quantity | |

| Pre-received Quantity |

NOTE: If the Inbound Shipment Detail includes multiple SKUs with different UOM, then, on the header, the quantity field is appended with an asterisk. But if it has multiple SKUs with a common UOM, the quantity fields are appended with the actual UOM on the header.

EMPTY LOCATIONS VIEW - ADDITIONAL FIELDS ADDED

The Web UI is enhanced to improve the Locate LPN workflow from the Empty Locations screen. Accessing these fields from the Empty Locations screen will save you time and effort.

The Empty Locations screen has been enhanced with the following new fields:

- Lock for Putaway flag

- Type

- Item Assignment Type (Permanent vs Dynamic)

- Item (If Permanent)

- Area

- Aisle

- Billing Location type

- Bay

- Level

- Bin

- Position

NOTE: The “Putaway Type” column is now renamed as “Location Size Type”.

As part of this enhancement, the search filter criteria has also been expanded to allow you to perform Partial Searches for Location Barcode.

NOTE: By default, these fields are hidden in the data grid. You need to add your choice of search fields from the list.

ALLOCATION SCREEN - ENHANCED FILTER CRITERIA

We have enhanced the Allocation screen by introducing additional columns so that you can have the list of filter criteria handy when narrowing down your preferred allocation. The following are the list of enhancements:

- The search option now has an Allocation UOM filter for the standalone Allocation screen (“Allocation View”) as well as the Allocation screen that is displayed from the Wave Inquiry screen.

- The Allocation UOM column and Order Sequence Number is now displayed on the data grid, by default for the Allocation and Wave Inquiry screens.

REPLENISHMENT TEMPLATE - SEARCH FILTER CRITERIA ADDED

The Replenishment Template is enhanced with following search filter criteria:

- Replenishment Zone

- Replenishment Rule

- Template Name

- Replenishment Trigger Mode

NEW SEARCH FIELDS FOR ITEMS IN MULTIPLE SCREENS

The Item Search feature has been optimized to help you search more efficiently using new search fields for Item Description. This enhancement helps you narrow down the scope of your search for the right SKU since an item in your warehouse can have different a Vendor Code and Internal Item Code.

The following table shows the newly added item description fields:

| SCREEN NAME |

ITEM SEARCH FIELDS |

|---|---|

| Inbound LPN |

Item Description, Item Description 2, Item Description 3 |

| Reserve Inventory |

Item Description, Item Description 2, Item Description 3 |

| Item Inventory by LPN |

Item Description 2, Item Description 3 |

| Allocation |

Item Description, Item Description 2, Item Description 3 |

| Outbound LPN |

Item Description, Item Description 2, Item Description 3 |

| ASN Detail |

Item Description, Item Description 2, Item Description 3 |

NOTE: By default, the new search fields will not be displayed on the data grid; you will need to add the desired columns.

Steps to Enable

You don't need to do anything to enable this feature.

Support for Swedish Translations

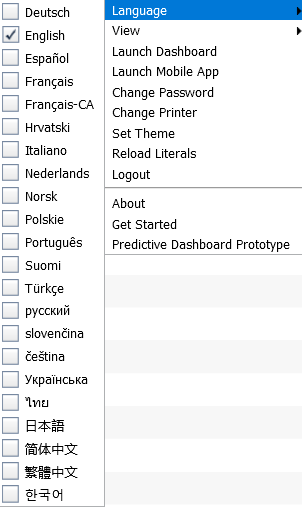

We’ve added support for Swedish language and translations in WMS. To see the list of supported languages:

- Click the user drop-down in WMS.

- Hover your cursor over Language. The list of languages will then display to the left.

User Menu Language Selection

Also, for the full list of supported language and valid field values, see the Literals tab in the Interface Specifications document. To access the latest Interface Specifications, go to the Oracle WMS Cloud Information Center. From the top of the page, click on the Documentation tab, then click the link under Current Documentation.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Inbound Logistics

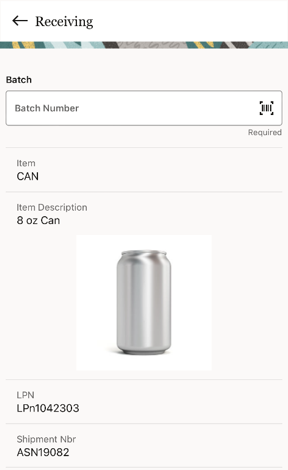

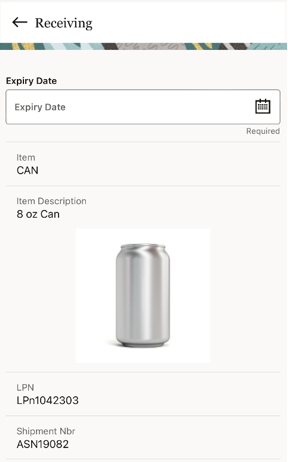

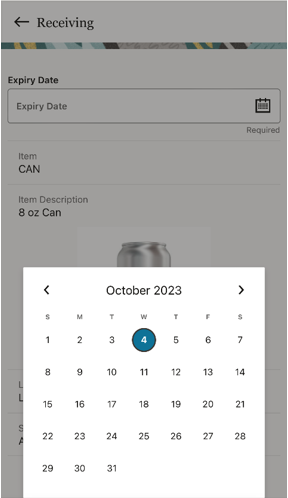

Support Receiving the Same Item in Different UOMs for the Same LPN

WMS is now enhanced to receive an item with Multiple UOM's on the shipment. This helps customers to send the item barcode having inventory details tracked in terms of Packs or Case, and also encourages you to receive the same SKUs in terms of Packs and Case. This functionality is implemented for Receive by Load (rf.inbound.cwrfrecvlpnload) and RF Receive by Shipment (rf.inbound.cwrfrecvlpnshpmt) and works in both SKU Scan and SKU Qty mode.

You can perform multiple UOM in both Infer and non-Infer UOM mode.

NOTE: In 23D, we have relaxed the restriction where the system displays an error “multiple UOM cannot be counted for same sku” and allow you to scan the item barcode corresponding to Case and Pack for the same LPN.

Receiving SKU with Multiple UOM via Infer Mode

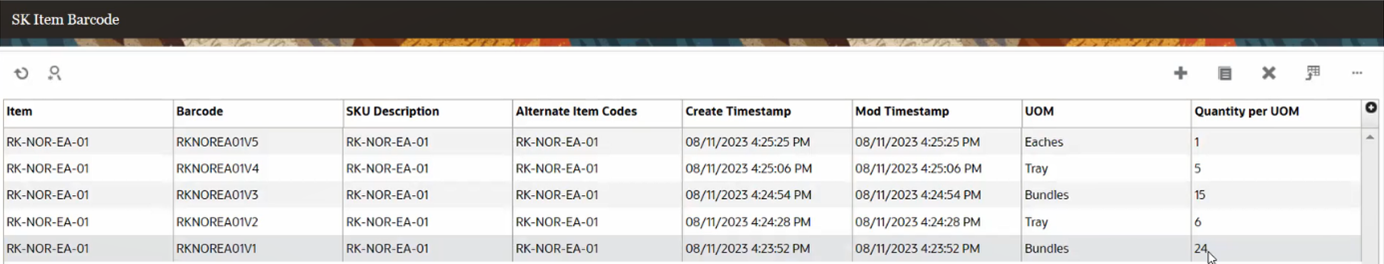

Let’s say your item barcode entity is defined with following UOM and quantity per UOM for an SKU.

Support to Receive Multiple UOM

When infer UOM from item barcode is enabled, on scanning the barcode corresponding to a record in the item barcode entity, the system picks the UOM and Qty per UOM, and defaults the same in the qty entry field. i.e., 1 Bundle (Case) =24 EA.

NOTE: The infer UOM from item barcode parameter works in parallel only when the item barcode entity is defined.

In Infer mode, if you want to receive the same SKU with multiple UOMs, you can now scan the preferred item barcode directly. i.e., Tray (here, Pack) = 6A.

NOTE: When receiving in non-infer mode, you can invoke the CTRL-K (Switch UOM) the change UOM. However, if the screen parameter is set to Infer UOM from Item Barcode and if the barcode scanned does not have “qty per UOM” configured, then the system falls back to displaying the Primary UOM.

If you scan the item barcode and UOM's associated with the item barcode is not of the same UOM class as the corresponding Item's Primary UOM, then the system displays an error "UOM from the barcode is not same of class as Item's Primary UOM" message.

NOTE: When the screen parameter is set to Infer UOM from item barcode, on scanning the item corresponding to case_uom and pack_uom, the hotkey CTRL+Q (Change Qty) functionality will be disabled.

- When you scan the pack barcode for the LPN, then the pack quantity is picked from the std_pack_qty and the case_qty is 0. Likewise, when the case barcode is scanned, the case_qty is picked from the std_case_qty of item_master and the pack_qty is 0 for the inventory.

- On receiving multiple UOM, the updates in IB Shipment, IBLPN, and IHT will always occur in terms of Primary UOM.

- On scanning an item corresponding to Case barcode and then Pack barcode for the same LPN, , ensure that the pack_qty is an integral multiple of the Case_qty scanned. Otherwise, the system displays a "Pack UOM needs to be integral multiple of Case UOM” error.

Steps to Enable

For RF Receiving:

- Go to RF Recv {lpn} Load (rf.inbound.cwrfrecvlpnload)/any other screens.

- Click Screen Parameters > qty-uom

- Select the parameter choice Infer UOM from Item Barcode drop-down menu.

- Click Save.

Key Resources

- See Configuring UOM topics.

Enhance Rule-Based Selection Criteria Screens

We have introduced new functions: "Unallocable Lock Code," "Expired LPN," and "Serial Number Count Mismatch" to enhance inventory management precision by facilitating the movement of inventory to the correct locations and ensuring accurate tracking of serialized SKUs.

Additionally, the new quality control filtering field streamlines QC processes. Improved filtering options in Movement Request selection and wave run management save time and improve order fulfilment accuracy.

We've introduced the following new field to the selection criteria where you can filter based on:

| Function |

Description |

|---|---|

| Unallocable Lock Code |

This function allows you to determine whether the LPN in scope has a Lock Code and whether that Lock Code's "Unallocable" flag is enabled or disabled. This feature helps you easily filter LPNs with allocable and unallocable lock codes, improving your inventory allocation process. |

| Expired LPN |

With this function, you can now check whether the corresponding LPN has any inventory records that are expired (that is, the expiry date is less than the current date). This capability aids in filtering out expired LPNs, ensuring that you're not allocating expired inventory. |

| Serial Number Count Mismatch |

For LPNs with serial tracking SKUs, this function validates whether the SKU quantity matches the serial number count. It helps you identify LPNs where the serial count does not equal the SKU quantity, ensuring accurate inventory tracking. |

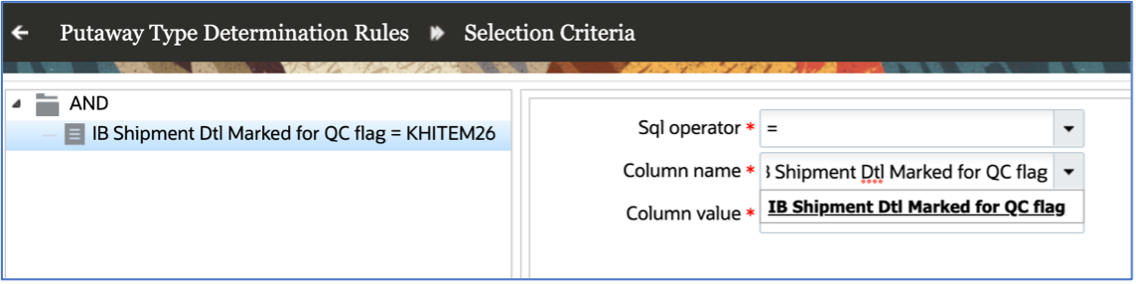

PUTAWAY TYPE DETERMINATION RULES

We have introduced a new selection criteria ‘IB Shipment Dtl Marked for QC flag’ to the Putaway Type Determination Rule > Selection Criteria to provide you more control and precision in the inventory management processes.

NOTE: These changes are not applicable to Pallet Putaway.

Putaway Type Determination Rules

This field offers four possible column values: Yes, No, True, and False, allowing you to easily differentiate between items requiring QC and items that does not requiring QC.

REPLENISHMENT MOVEMENT REQUEST SEARCH

We have introduced an enhanced filtering capabilities to streamline your Movement Request selection process for wave runs.

Now, you can utilize the following fields to refine your search:

-

Movement Request Header Internal Movement Request Flag

WAVE DYNAMIC SEARCH

We have introduced an array of new filtering options across three key user interfaces: Wave Template - Dynamic Search, Task Creation Template, and Cubing Rule.

These new fields empower you to efficiently pinpoint the orders that align with your specific criteria, enhancing your overall wave run management experience.

Here are the newly available fields:

| Screens | Fields |

|---|---|

| In Wave Template - Dynamic Search: |

|

| In Task Creation Template: |

|

| In Cubing Rule: |

|

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Improvements to Receiving REST API

In 23C, for non-cartonized receiving, we enhanced the item list of Receive API to handle the additional fields batch number, expiry date, serial numbers, PO number, and PO Sequence number. In continuation with that, you can now perform receiving updates with inventory attributes.

With 23D release, for non-cartonized receiving, we have enhanced the Receive API item list to include the “inv_attr_x” field.

| Fields added in Item List |

Description |

Required |

Type |

|---|---|---|---|

| inv_attr_x (x varies from ‘a’ to ‘o’) |

Value provided for inventory attributes a-o |

C (If item is tracking corresponding inventory attribute, then respective inventory attribute is mandatory.) |

String |

POINTS FOR CONSIDERATION:

- If the item is inventory attribute tracked, on passing a null value in the inv_attr_x field, the API returns an error message "Item is inv attribute tracked".

- If the item is not tracking the inventory attributes, you can still pass ‘inv_attr_x’ field in the item list as a pass-through field.

- While passing attributes the system looks for item if item is tracking inventory attributes or not.

- If you pass an inventory attribute value that does not match with the configured inventory attribute barcode type, then the API returns an error message "Barcode type mismatch".

- If the passed inventory attribute doesn’t honor the column formatting rule, then the API displays an error.

- If an unanticipated inventory attribute value is passed in the API, then the API creates a new detail line with the new value passed in the API and shipped quantity as ‘0’.

EXAMPLE BODY

For example, if an item is tracking batch, inventory attributes, expiry, and serial numbers, the following is an example body for Receive API functionality:

{

"item_list": [

{

"item_barcode": "ITEM1234",

"qty": 5,

"receiving_uom":"LB",

"po_nbr": "VUPO123",

"po_seq_nbr": 001,

"batch_nbr": "BATCH11",

"invn_attr_a": "123",

"invn_attr_b": "363",

"expiry_date": "20231211",

"serial_nbr_list": ["SRL-1", "SRL-2", "SRL-3", "SRL-4", "SRL-5" ]

}

{

"item_barcode": "ITEM5678",

"qty": 5,

"receiving_uom":"LB",

"po_nbr": "VUPO123",

"po_seq_nbr": 002,

"batch_nbr": "BATCH12",

"invn_attr_a": "AA12",

"invn_attr_b": "AB163",

"invn_attr_c": "AN1262",

"expiry_date": "20231111",

"serial_nbr_list": [ "SRL-1", "SRL-2", "SRL-3", "SRL-4", "SRL-5"]

}

]

}

EXTENDING SUPPORT TO PO BASED API RECEIVING

The Receive API has been expanded to send either the shipment number or Purchase Order (PO) number at the header level. If you send the PO number at the header level, then the PO sequence number passed at the detail level (item list) will be used for figuring out the corresponding detail.

If you pass the PO number at the header without passing the shipment number, API still supports the passing of the batch number, inventory attribute, serial numbers, and expiry.

POINTS FOR CONSIDERATION:

- If you pass a PO number at the header level and the detail level (item list), then the API displays an error message "Cannot have PO number at header and item list level". So, we suggest passing PO number at the Header level and PO Sequence number in the item list.

- If you are performing a shipment based receipt by passing shipment number, send po number and PO Sequence number at the detail level.

- If you pass an invalid/non existing PO number in the Receive API Header, the API returns an error message "Purchase order doesn't exists".

- This applies for both Cartonized and Non-cartonized shipments.

EXAMPLE BODY

For example, if the PO number is passed at the header level, the following is an example body for Receive API functionality:

{

"facility_id_code": "FAC",

"company_id__code": "COMP",

"po_nbr": "TESTPURORD1",

"container_nbr": "CNTRNBR",

"item_list": [

{

"item_barcode": "ITEM1234",

"po_seq_nbr": "001"

"qty": 10,

"pack_qty": 5

}

]

}

For more information on Receive API item list for Non-Cartonized shipments, refer the Extend Receive API to Support Serial, Lots, and Expiry Date topic in the 23C – What’s New.

RECEIVE API FOR CARTONIZED SHIPMENT WITH THE ITEM LIST

For cartonized shipments, the Receive API item list is expanded to support the additional fields batch number, expiry date, serial numbers, PO number, PO Sequence number, and inventory attributes.

For cartonized receiving, the following fields are added to the item list of Receive API.

| Fields added in Item List |

Description |

Required |

Type |

|---|---|---|---|

| po_nbr |

Purchase order number |

C |

String |

| po_seq_nbr |

Purchase order sequence number |

C |

Integer |

| batch_nbr |

Batch number |

C (If item is batch tracked, then batch number is mandatory.) |

String |

| expiry_date |

Expiry date for a batch |

C (If item is expiry tracked, then expiry date is mandatory. However, if existing batch has expiry date, then expiry date is not mandatory.) |

Date |

| serial_nbr_list |

List of serial numbers in an LPN |

C (When the company is configured for end-to-end serial tracking, then serial number is mandatory.) |

String |

| inv_attr_x (x varies from ‘a’ to ‘o’) |

Value provided for inventory attributes a-o |

C (If item is tracking corresponding inventory attribute, then respective inventory attribute is mandatory.) |

String |

| qty |

Value provided as a part of cartonized receipt |

C |

Number |

POINTS FOR CONSIDERATION:

- If you are not passing the item list, then the API honors the shipment detail information from the Inbound Shipment Detail screen.

- For a cartonized shipment, you can receive a batch, expiry, serial, or inventory attribute tracking item without item list through Receive API, for additional information refer “RECEIVE API FOR CARTONIZED RECEIVING” section in the Extend Receive API to Support Serial, Lots, and Expiry Date topic in the 23C – What’s New.

- While receiving a cartonized shipment, if item list argument is passed, then the API honors the information passed in the item list. If you are passing item list without the information related to tracked lot/expiry/serials/inventory attributes, the API will not pick up the details from shipment detail.

-

If an item is tracking batches/expiry date/serials/inventory attributes then the respective information needs to be passed in the API, even if it can be inferred from the shipment detail.

-

You can pass either case_qty or pack_qty values in a request. If you pass both values, the API returns an error message.

-

Serial tracking item doesn't support receiving in terms of cases or packs (case_qty or pack_qty).

-

If you pass the item list without the “qty” value, the API returns an error to the API caller.

- If the receiving LPN is marked for detailed receipt and the item list is not passed, then the API returns an error message "LPN marked for detailed receipt, item list is not shared, cannot receive LPN".

- If you send an SKU in the item list that is not a part of the shipment detail for the LPN being received but part of the overall shipment, the API creates a new record in the shipment detail with “0” shipped quantity. This gives an indicator that an unanticipated SKU for the LPN is received.

- If the SKU shared in the item list is neither a part of the LPN being received nor a part of the overall shipment, then the API returns an error message.

- If you send a batch number other than the batch number that is present in the shipment detail, the system creates a new row in the Inbound Shipment Detail with “0” shipped quantity and records the received quantity. The same behavior applies to inventory attributes and expiry date.

- If you send serial numbers in the item list, the number of serial numbers shared should be equal to the quantity corresponding to the item/batch/expiry/inventory combination for the LPN being received.

- If you receive a batch, expiry, serial, or inventory attribute tracking item and the item list shared does not include appropriate batch, expiry, serial, or inventory attribute information then the API returns an error message.

- If you pass an inventory attribute value that does not match with the configured inventory attribute barcode type, then the API returns an error message "Barcode type mismatch".

EXAMPLE BODY

For example, if an item is tracking batch, inventory attributes, expiry, and serial numbers, the following is an example body for Receive API functionality:

{

"facility_id_code": "FAC",

"company_id__code": "COMP",

"shipment_nbr": "VUSHIP0013B",

"container_nbr": "CNTRNBR",

"item_list": [

{

"item_barcode": "ITEM1234",

"qty": 5,

"receiving_uom":"Units",

"batch_nbr": "BATCH11",

"expiry_date": "20231211",

"invn_attr_a": "123",

"invn_attr_b": "326",

"serial_nbr_list": ["SRL-1", "SRL-2", "SRL-3", "SRL-4", "SRL-5"]

}

]

}

TRACKING OF MANUFACTURE DATE IN RECEIVE API

To provide you with more flexibility, now you can pass the manufacture date information using the Receive API. This is useful in cases where you are only provided with the manufacture date information.

There is no need to provide both dates if your item is expiry tracked. The following field is added to the item list of Receive API.

| Fields added in Item List |

Description |

Required |

Type |

|---|---|---|---|

| manufacture_date |

Manufacture date |

C (If item is expiry tracked, then either expiry date or manufacture date is mandatory to pass.) |

Date |

NOTE:

- Manufacture date should be passed in “YYYY-MM-DD” format.

If you pass the manufacture date for an expiry tracked item, the API calculates the expiry date based on the product life days configured. Then the API records both expiry date and manufacture date.

If you pass the manufacture date for an item that doesn’t track expiry, the API will not perform calculations for expiry date. The API will not record the expiry date and the manufacture date.

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

Split Inbound LPNs Marked for Quality Control (QC)

In 23D, Oracle Warehouse Management is enhancing the Split LPN module to consider inventory marked for QC using a new screen parameter “allow-split-for-qc-lpns”.

As a warehouse user, you may have run into scenarios where some inventory that has come in for quality check contains both damaged and intact items. Without having to approve the entire inventory, split the damaged inventory into different LPNs and then apply lock codes for the damaged inventories, you can now separate the inventory that is marked for QC. This enhancement saves you time and optimizes the workflow as you can approve or reject the inventory after splitting it in QC.

INVENTORY HISTORY UPDATES

The Inventory History records for different operations using the “allow-split-for-qc-lpns” parameter are written as follows:

| CONDITIONS | INVENTORY HISTORY | REFERENCE VALUE | REFERENCE CODE |

|---|---|---|---|

| On performing a split LPN transaction for inventory marked for QC |

IHT-34 Split Container Before ASN Verification |

‘Yes’ in REF_VALUE_10 |

SQC (Split for Quality Check) in REF_CODE_10 |

| On cancelling LPNs marked for QC |

IHT-33 Split Container Cancelled |

‘Yes’ in REF_VALUE_10 |

SQC (Split for Quality Check) in REF_CODE_10 |

| When a Lock is applied for LPNs marked for QC |

IHT-36 Split Container - Lock Acquired |

'Yes’ in REF_VALUE_13 |

SQC (Split for Quality Check) in REF_CODE_13 |

| On performing a split LPN transaction for inventory not marked for QC |

IHT-34 Split Container Before ASN Verification and IHT-35 Split Container Cancelled |

‘No’ in REF_VALUE_10 |

SQC (Split for Quality Check) in REF_CODE_10 |

| IHT-36 Split Container - Lock Acquired |

‘No’ in REF_VALUE_13 |

SQC (Split for Quality Check) in REF_CODE_13 |

|

| On performing a split LPN transaction |

IHT-35 Split Container After ASN Verification |

‘No’ in the REF_VALUE_10 |

'SQC' (Split for Quality Check) in REF_CODE_10 |

The Split LPN transaction is applicable for “To LPN” that is marked for QC and is associated to the same inbound shipment as “From LPN”. Inbound Shipment details are updated when the Split transactions are performed for scanned “To LPN” which are marked for QC.

For new Inbound LPNs, the same inventory updates are reflected when the Split transaction is performed. The Split LPN transaction for “To LPN” that is marked for QC can be linked to multiple Purchase Orders and the inventory updates will be reflected on both Inbound Shipments and Purchase Orders accordingly.

Steps to Enable

To allow Split LPN for inventory that is marked for QC, configure the screen parameter “allow-split-for-qc-lpns” by setting the drop-down values to YES, NO or Blank.

- To perform the Split LPN transaction for inventory marked for QC, set the 'allow-split-for-qc-lpns' to YES. The system continues to support split transactions for LPNs in other statuses such as “Received” and “Located”.

- If you set the 'allow-split-for-qc-lpns' as NO or if left blank, the system allows you perform split transactions as previously configured except for inventory marked for QC.

NOTE: By default, the 'allow-split-for-qc-lpns' parameter is set as 'Blank'.

Key Resources

Inventory Operations

Generate Inventory Balance Snapshots by ERP Bucket

In Warehouse Management, Custom Inventory Summary provides different inventory information including total inventory in Inbound LPNs, active locations, and total inventory allocated. These are detailed buckets for the four wall inventory. For better integration between WMS and ERP systems, WMS needs to communicate inventory information at a summary level broken down by inventory attributes, lots, and serials for example. ERP buckets are configured at the lock code level in WMS. ERP buckets can be configured to correlate different sub-inventories in Inventory Management/ERP systems.

WMS communicates inventory changes with respect to ERP buckets via inventory history which keeps the ERP system up to date. This new snapshot allows you to reconcile inventory balances between WMS and Inventory Management via ERP buckets.

From 23D onwards, you can now generate a new snapshot of inventory at the ERP bucket level broken down by the following:

- Expiry Dates, Inventory Attributes, Batches and Serials

The following sections will describe the setup needed in Warehouse Management to generate and extract inventory snapshots.

There are two types of Inventory Snapshots:

- Inventory Balance Snapshot by ERP Bucket

- Inventory Balance Snapshot by Location

There are three High-Level steps involved:

- Generation (using rules and a scheduled job)

- Extraction (using rules and a scheduled job)

- From the Output Interfaces screen, download files produced by the Extraction job.

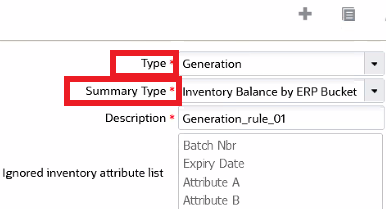

ITEM SUMMARY GENERATION RULES UI

A new UI, Item Generation Summary Rules, allows you to define selection criteria which will generate the specific inventory information you need to support ERP Bucket and sub inventory information needed for ease of integration. From this UI, you can create both Generation and Extraction Rules.

In the selection criteria, you can create rules with the following rule types:

- Generation

- Extraction

Item Summary Generation Rules

You can also select the following summary types to define the selection criteria by Location or ERP Bucket:

- “Inventory Balance By Location”

- “Inventory Balance by ERP Bucket”

Ignored inventory attribute list will help in additional grouping of inventory attributes. This field gives you the option to exclude certain attributes in the item summary information.

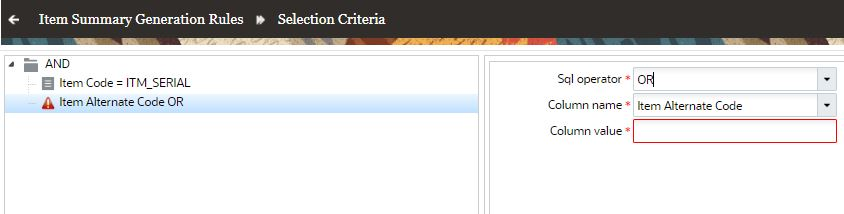

You can filter the inventory snapshot based on item properties including the following:

- Item Alternate Code

- Item part_a

- Item part_b

- Item part_c

- Item part_d

- Item part_e

From the Item Summary Generation Rules UI, you can also filter location information. The following location fields are available from the selection criteria:

- Location Area

- Location Aisle

- Location Size Type

- Location Replenishment Zone

- Location Lock Code

- Location Alloc Zone

These fields are also available in the Selection Criteria in the Item Summary Generation Rules UI:

Selection Criteria

EXTRACTION RULE TYPE

You can also extract item summary data via the Item Summary Generation Rules UI. When the rule type is "Inventory Balance by ERP Bucket", from the Selection Criteria screen, you can now create a rule with the following item-related options in the selection criteria:

- ERP buckets (Lock Codes)

- Create_ts

- Max mod_ts

- Batch Nbr

- Expiry Date

- Inventory attributes A to Inventory attribute 0

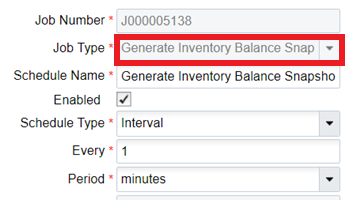

NEW SCHEDULED JOB TYPE – GENERATE INVENTORY BALANCE SNAPSHOT

To seamlessly provide Inventory Summary by ERP Bucket information for integration between Warehouse Management and Inventory Management Cloud, a new Scheduled Job Type “Generate Inventory Balance Snapshot” is available in the Search pane of the Scheduled Jobs UI.

This scheduled job will determine the latest inventory balances by ERP buckets for each SKU based on the selection criteria rules. The data will be in an intermediate table first, from which the extraction job will then pull the data and create the inventory snapshot payload.

This scheduled job type allows you to filter data so that it can pull the relevant ERP Buckets and Sub Inventory information.

Generate Inventory Balance Snapshot

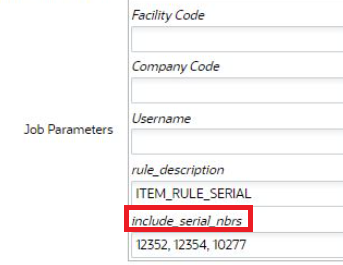

In the Scheduled Job Parameters details you can use the "include_serial_nbrs" field to configure which serial numbers you would like to include in the output file.

Include Serial Numbers

NEW SCHEDULED JOB TYPE - EXTRACT INVENTORY BALANCE SNAPSHOT

To assist in extracting inventory data that is relevant to ERP Buckets/sub-inventory a new Scheduled Job Type Extract Inventory Balance Snapshot is available. The Extract Inventory Balance Snapshot job type allows you to configure the job type with a rule description and then pull the inventory summary information in a report.

NOTE: The Generation job needs to complete first before running the Extraction job and before making output interface files with data.

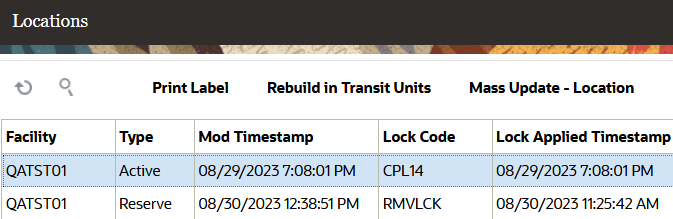

UPDATE LOCK CODE APPLIED TIME STAMP

When the system is extracting inventory summary data, the system pulls ERP bucket information based on the setting of the company Parameter "HONOR_LOCK_CODE_PRIORITY."

For scenarios where "HONOR_LOCK_CODE_PRIORITY is not configured, the lock_applied_time stamp allows the system to determine which lock code was applied first. The lock_applied_time stamp will be updated at the Batch Master and Location level.

Lock Applied Timestamp

NOTE: For arriving at ERP bucket information, the lock_applied_time stamp field will not be populated by default. The system will fall back to the batch or location modified time stamp.

PATCH API SUPPORT FOR BATCH ENTITY

The lock_applied_time stamp field will be updated on the Batch Master entity when a new lock code is applied using the Patch Support API for Batch Entity.

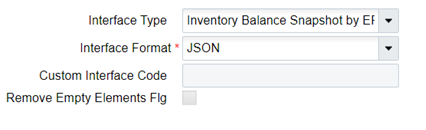

INVENTORY BALANCE SNAPSHOT BY ERP BUCKET AND LOCATION - NEW OUTPUT INTERFACES

Providing additional support for gathering inventory information, two new output interface types "Inventory Balance Snapshot by ERP Bucket" and “Inventory Balance Snapshot by Location” are now available. You can create and configure both of these interface types in the Output Interface Configuration UI. You can specify the generation of JSON formats.

JSON Format

Both interfaces allow you to use the data from the Generate Inventory Balance Snapshot scheduled job. Once the "Generate Inventory Balance Snapshot" scheduled job runs to completion, the system will generate an " INV_BALANCE_BY_ERP_BUCKET" output file.

In the Output Interface Configuration UI, you can specify the generation of JSON format for the output. The following are the JSON document properties:

| Property | Value |

|---|---|

| Entity | ITEM_INV_BALANCE_BY_ERP_BUCKET |

| File Prefix |

ITEM_INV_BALANCE_BY_ERP_BUCKET: IBE |

FIELD SELECTION USING TREE FILTERS

The Inventory Balance By ERP Bucket and Inventory Bucket By Location output interfaces have been enhanced to support the use of tree filters. This helps you reduce clutter and eliminate redundant fields as you can arrange the fields in a tree structure hierarchy. Now, you can easily check the box for a required field and, likewise, uncheck the box for a field you want to hide.

Steps to Enable

- From the Item Generation Summary Rules UI, create a Rule Type as Generation or Extraction. Then define the Summary Type as “Inventory Balance by ERP Bucket" or "Inventory Balance By Location.”

- From the Selection Criteria screen, you can now create a rule with the items you want to include in your output file.

- From the Output Interfaces screen, download files produced by the Extraction job.

Key Resources

Support Cycle Counting the Same Item in Different UOMs for the Same LPN/Location

With infer UOM from Item barcode enabled, WMS now allows you to cycle count the same item in different UOMs for the same LPN or Location, simplifying cycle count processes and reducing redundant case/pack opening while cycle counting, as well as minimizing counting errors.

- If the scanned barcode corresponds to item barcode entity, then the system picks the UOM, quantity per UOM, and defaults the same in the Quantity entry field.

- You now have an ability to perform cycle count for an item which has Multiple UOM's present in the location.

- In 23D, we have relaxed the restriction where the system displays an error “multiple UOM cannot be counted for same sku” and allow you to scan the item barcode corresponding to Case and Pack for the same LPN.

NOTE: On scanning an item corresponding to Case barcode and then Pack barcode for the same LPN, then the pack_qty must be an integral multiple of the Case_qty scanned. Otherwise, the system displays an [Pack UOM] needs to be integral multiple of [Case UOM]” error.

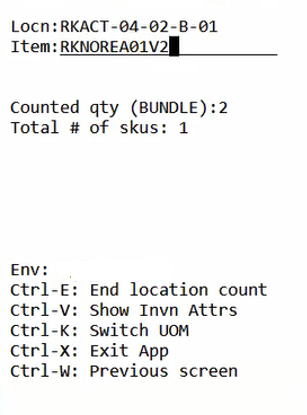

SKU SCAN MODE

On performing RF Cycle Count in SKU scan mode, the system allows you to scan combinations of multiple UOM barcode (Primary_UOM, Case_UOM, or Pack_UOM) for the same LPN.

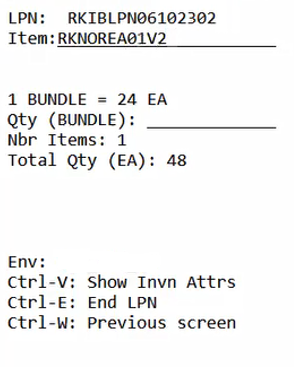

For example, lets say you scan item barcode corresponding to Case of 24 bundles, and then you scan item barcode corresponding to Packs of 6 tray.

Support CC in Multiple UOM

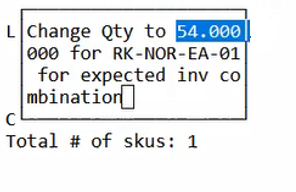

NOTE: On scanning items with different UOM for the same LPN, the system displays a (*) in the counted qty field.

On scanning the item barcode, the system picks the UOM from item barcode scanned and updates the count accordingly (54).

NOTE: In SKU-scan mode, the system interprets in terms of Cases or Packs from item barcode.

- If the screen parameter is set to Infer UOM from Item Barcode and if the barcode scanned does not have “qty per UOM” configured, then the system falls back to displaying the Primary UOM. In such case, you can use the control key (CTRL+K) to switch UOM and can proceed counting in Multiple UOMs.

NOTE: If you perform cycle count in non-Infer mode, you can continue to cycle count the SKU with multiple UOMs by invoking the control key (CTRL+K) to switch UOM.

- When you scan the pack barcode for the LPN, then the pack_qty is picked from the std_pack_qty and the case_qty is 0. Likewise, when the case barcode is scanned, the case_qty is picked from the std_case_qty of item_master and the pack_qty is 0 for the inventory.

NOTE: When qty-uom screen parameter is set to "Cases/Packs/Units" and content-count is set to "By Sku Scan", the system now displays a modified error message "Sku Scan Mode not supported when qty entry is by Cases/Packs/Units".

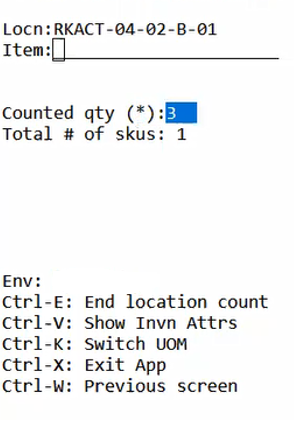

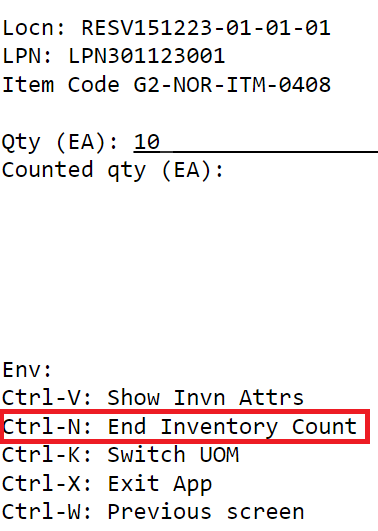

SKU-QUANTITY MODE

On performing RF cycle count in SKU qty mode, the system allows you to scan combinations of multiple UOM barcodes for the same LPN.

As we expand multiple UOM Cycle Count to Infer UOM from the item barcode, a new screen parameter 'recount-on-end-sku-count' is introduced with parameter option Yes/No, to recount on ending the SKU count for both Infer and Non-Infer mode.

NOTE: When you create a Cycle count task in Infer mode and execute the transaction, the records move to Ready status. At this stage, you need to explicitly select the record(s) to cancel them.

Infer Mode

- On performing cycle count in Infer mode with “recount-on-end-sku-count” parameter to Yes, you can count multiple UOM from item barcode, recount SKU upon ending count, and also perform CTRL+K(Switch-UOM).

NOTE: If recount-on-end-sku-count - No/Blank (default), you cannot invoke the hotkey CTRL+K(Switch-UOM) on performing multiple uom cycle count.

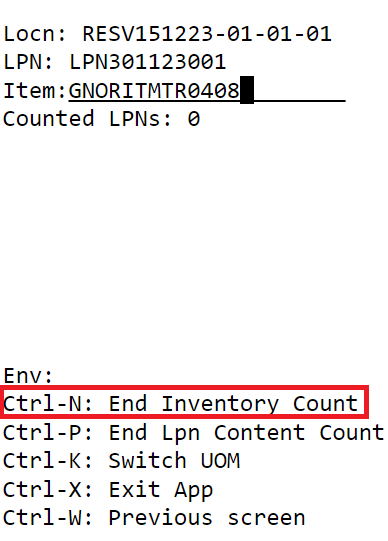

- We have introduced the control key “CTRL+N (END Inventory Count)” to End SKU count after counting (Multiple UOM) for all the inventory present in the location for a particular item and proceed to count for others. That is, you can continue counting for the same SKU with different UOM's, until you hit CTRL-N (End Inventory Count).

Infer Mode

- When you invoke CTRL-E, then the location count ends and updates happen accordingly.

NOTE: This control key 'CTRL+N' is disabled, by default and when recount-on-end-sku-count - No/Blank. To utilize this feature, you need to enable only set recount-on-end-sku-count to Yes.

Non-Infer Mode

- On performing cycle count with non-Infer mode, on scanning a barcode, the system picks the qty in terms of primary_uom. You can invoke hot key CTRL+K to switch UOM and enter the qty in case_uom and continue to scan different UOM through the hotkey.

- The newly introduced control key CTRL+N (End Inventory Count) can be invoked even in non-infer mode to end an inventory counting multiple UOM for all inventory present in the location. This control key 'CTRL+N' is disabled, by default and when recount-on-end-sku-count - No/Blank. To utilize this feature, you need to set “recount-on-end-sku-count” to Yes.

NOTE: When you perform recount, the system disables the key CTRL-P: End LPN Content Count because the count will not be considered until you recount the inventory.

Non-Infer Mode

On ending the inventory (CTRL+N), the system picks the UOM from item barcode scanned and update the count accordingly.

Counted Qty field.

We have also added the 'Counted qty' field in the Qty scan screen. This field clears on performing CTRL-N for Recount and CTRL-N on Ending Count.

Steps to Enable

For RF Cycle Count (locn):

- Go to RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn)

- Click Screen Parameters > qty-uom

- Select the parameter choice Infer UOM from Item Barcode drop-down menu.

- Click Save.

Key Resources

- See Configuring UOM topics.

Perform Create LPN in Cases and Packs

Warehouse Management is offering continued flexibility for managing Unit of Measure (UOM) for inventory. You can now perform RF Create LPN transactions with other UOMs from a different UOM class as the item primary UOM. This provides more simple and efficient management of your inventory.

RF CREATE LPN - NEW SCREEN PARAMETER TO SUPPORT CASES/PACKS/UNITS

When using the RF Create LPN transaction, you now have the option to enter the number of cases rather than just entering the primary UOM. Having the option to perform RF Create LPN in terms of cases will reduce the burden on operations where they previously had to perform calculations to arrive at the quantity needed for the primary UOM. Handling inventory in terms of cases will increase productivity and help prevent errors.

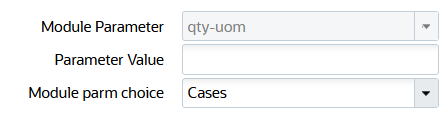

A new screen parameter “quantity-uom” has been added to the RF Create LPN (rf.inbound.cwrfcreatelpn) module. The following UOM values are added to the screen parameter:

- Units (blank/default)

- Packs

- Cases

- Cases/Packs/Units

Quantity UOM

BEHAVIOR FOR RF CREATE LPN – QUANTITY UOM PARAMETER

The following table shows the behavior for entering quantities using the RF Create LPN - Quantity UOM parameter depending on whether it is set to Cases, Packs, Units or Cases/Packs/Units:

| Quantity-UOM Parameter Choice | Behavior |

|---|---|

| Cases | Quantity entry mode will assume that the quantity to be captured is in terms of the Case UOM of the item. The UOM displayed will be as per the Case UOM of the item. If the scanned SKU does not have std_case_quantity populated, then the system displays the error message "Case Quantity not configured for the SKU". |

| Packs | Quantity entry mode will assume that the quantity to be captured is in terms of the Pack UOM of the item. The UOM displayed will be as per the Pack UOM of the item. If the scanned SKU does not have std_pack_quantity populated, then the system displays the message "Pack Quantity not configured for the SKU". |

| Units | Quantity entry mode will assume that the quantity to be captured is in terms of the Eaches UOM of the item. The UOM displayed will be as per the Units UOM of the item. |

| Cases/Packs/Units | Quantity entry mode will assume that the quantity to be captured is in terms of the either of the configured values or a combination of "Cases/Packs/Units" UOM of the item. NOTE: If the quantity-uom screen parameter is set to "Cases/Packs/Units" and the create-lpn-mode screen parameter is set to By SKU Scan, then the system displays the following error after scanning the LPN "SKU Scan Mode not supported when quantity entry is by Cases/Packs/Units". |

RF CREATE LPN - ALLOW USERS TO CHANGE DEFAULT UOM USING HOT KEY

When receiving inventory, you may want to navigate to different screens in the RF to receive the relevant UOM. Warehouse Management allows you to change the UOM in RF Create LPN with the help of a hotkey without being logged out of the transaction.

In addition to the existing transactions, the “CTRL-K: Switch UOM Display” hotkey has also been added to:

- RF Create LPN (rf.inbound.cwrfcreatelpn)

INVENTORY CASE/PACK QUANTITY - SYSTEM WARNING

If the case or pack quantity is 0 for inventory, RF Modify LPN will now display a warning and prevent you from changing the quantity in terms of packs or cases.

Steps to Enable

- From the RF Create LPN (rf.inbound.cwrfcreatelpn) module -> screen parameters, select “qty-uom”.

- Click Edit and select the desired UOM from the drop-down menu.

- Click Save.

Key Resources

- For more details, see Introduction of Hotkey to Change UOM in Receiving.

Perform Non-Tasked Cycle Counting for a Specific Item in Deferred Mode

Your picking locations (active locations) may contain different kinds of Items kept in the same location or distinct batches or expiry of the same item. Earlier, cycle counting was not permitted in the deferred mode for item inventory combinations. WMS now allows you to cycle count a specific item or item inventory combination in an active location in deferred mode. This will help you to cycle count and approve specific Items without affecting the other items in the same location and ensuring inventory accuracy.

CYCLE COUNT ADJUSTMENT HEADER/DETAIL UI IMPROVEMENTS

You can now differentiate between normal counting at the location level vs specific SKU/Inventory Counting in Cycle Count Adjustment UI. This helps to perform cycle count approvals effectively.

A new flag “update-inventory-mode” is introduced in the Cycle Count Adjustment Header UI. You can utilize this feature, and set the parameter update-locn-invn-mode with the following parameter choices:

| update-locn-invn-mode | Behavior |

|---|---|

| All items | Writes CC Adjustment Header record with update-inventory-mode set to "All Items". |

| Counted Items Only | Writes CC Adjustment Header record with update-inventory-mode set to "Counted Item". |

| Counted Item Inventory Combination | Writes CC Adjustment Header record with update-inventory-mode set to "Counted Inventory". |

You also search the CC Adjustment Header records based on this field “update-inventory-mode”. You can also add this flag to the data grid by enabling it, explicitly.

NOTE: For existing CC adjustment records where update-inventory-mode value is blank, the system displays the value as "All Items".

When update-locn-invn-mode is set to Counted Item or Counted Item Inventory and Facility/Company Parameter set to perform deferred counting:

- When the “update entire location” is set to No, the system displays an error message (code-1669) "Deferred Counting is not supported ".

- If the update-locn-invn-mode is set to All Items and/or is set to Counted Item, or Counted Inventory with “deferred approval mode” set to Skip CC deferred adjustments, then the system does not display the message.

- For anticipated Items or Inventory that are not counted, the system does not write cycle count Adjustment Rule header/detail record.

- When the deferred-approval-mode" screen parameter is set to manual approval, then the system writes the Cycle Count Adjustment header/details UI record.

For example, the following table lists a few conditions when the status is displayed as "No Variance”. On any variance, the system writes the record with the status "Pending".

| update-locn-invn-mode |

CC Adjustment header/detail with status = No Variance |

CC Adjustment header/detail with status = Pending |

|---|---|---|

| Counted Items only |

|

|

| Counted Item Inventory Combination |

|

|

CYCLE COUNT ON APPROVAL BY RULE

Cycle Count Location is expanded to write the records to Cycle Count Adjustment Rules Header/Detail UI based on approval rule when update-locn-invn-mode is configured with Counted Items only or Counted Item Inventory Combination.

| update-locn-invn-mode |

Approval by Rule |

Behavior |

|---|---|---|

| Counted Items Only |

SKU |

Rules apply for counted SKU only. |

| Counted Items Inventory |

Inventory |

Rules apply for counted Inventory only. |

| Counted Items Only |

Inventory |

Rules apply for counted Inventory and not for uncounted SKU's. |

| Counted Items Inventory |

SKU | Ignores the rule sequence based on SKU and prioritizes the rule sequence based on Inventory. |

NOTE: When the deferred-approval-mode is set Approval by Rule, then system displays “Deferred Counting is not supported” when update entire location is set to No. We’ve relaxed this hard error message to a warning message with option to accept or proceed. However, if you wish to retain the message as hard error, you need to set the message setting to Auto reject the approval.

APPROVE/REJECT CYCLE COUNT ADJUSTMENT DETAIL RECORDS PER SKU OR BY INVENTORY

You can now Approve/Reject the CC Adjustment detail records for the counts performed when update-inventory-mode is set to "Counted Inventory/Counted Items". Keep in mind the following when update-inventory-mode is set to Counted Items or Counted Items/Inventory:

- If there is a discrepancy for anticipated SKU/inventory combination counted, then the system writes IHT-19 Cycle Count Adjustment Active with one of the reference fields populated with Code as "IUM" and Ref Value as "Counted Items/inventory".

- If there is an anticipated SKU/Inventory combination without any discrepancy counted, then the system writes IHT-42 Cycle Count - Active SKU Counted with one of the reference fields populated with Code as "IUM" and Ref Value as "Counted Items/inventory".

- If an unanticipated SKU/Inventory is counted, then the system also writes ** IHT-19 Cycle Count Adjustment Active with one of the reference fields populated with Code as "IUM" and Ref Value as "Counted Items" if update-inventory-mode is set to Counted Inventory.

NOTE: When the CC Deferred Adjustment UI has two records for the same location, when approving the count for one record, the system displays the error message "Location %LOCATION_STRING already has a pending cycle count with Update Inventory Mode set to %UPDATE_INVENTORY_MODE%".

Steps to Enable

Steps to Enable:

- Go to RF Cycle Count Location (RF-Text: Cycle Cnt {locn})

- Click screen parameter > update-inventory-mode. Select the parameter and click edit.

- Choose the module parameter from the drop-down menu.

- Click Save.

Key Resources

Auto Removal of Inherited Lock Code on LPN When Transferring from a Location

During some receiving business flows, there is a need to push inventory or LPNs to individual locations/departments (such as Inspection, Marketing etc.) where each department will have its respective location and location lock code configured.

For example, marketing departments may have a (MRKT) lock code and Inspection departments may have a (QC) lock code. When inventory is moved to those locations, the LPNs will inherit the location lock code. In this case, it is difficult to find which LPNs are navigated to which department. So, with 23D release, when you move inventory from one location to another location, the system now removes the inherited location lock.

UI CHANGES:

We have added a new Lock Code type flag “Remove Inherited Location Lock on Unlocate” to the Lock Code UI.

- The flag is now available in Create and Edit Pane of the Location UI.

- By default, the new flag value is hidden in the UI grid. You can select and add it to the preference view.

NOTE: If the field is exposed in the grid, then the same will be exposed as part of the CSV export.

- Additionally, the flag is added to the Selection Criteria to filter the location where the flag is enabled or disabled (drop-down with Yes/No).

The behavior of the lock code is described below:

| “Remove Inherited Location Lock on Unlocate” flag is enabled Yes/No |

Behavior |

|---|---|

| Yes |

On exiting from the location,

|

| No |

LPN have same lock code (previous location) when the LPN is moved out of the location. |

NOTE:

- By default, the “Remove Inherited Location Lock on Unlocate” flag is unchecked.

- If there are multiple lock codes on the LPN, the system removes the lock code that matches with the location lock code.

- The behavior remains the same when you create an LPN from active location.

If you create an LPN from active location and the flag is enabled then:

| Case |

Behavior |

|---|---|

| Moving inventory into a new IBLPN |

|

| Moving inventory into an existing IBLPN that does not have lock code |

|

| Moving inventory into an existing IBLPN that has a lock code which is not same as location lock code |

|

| Moving inventory into an existing IBLPN that has a lock code which is same as location lock code |

|

MODULES UPDATED IN “REMOVE INHERITED LOCATION LOCK ON UNLOCATE” FLAG

We have multiple ways to move inventory from one location to another. So, the new flag “Remove Inherited Location Lock on Unlocate” is updated for the following modules:

- RF Inbound Locate LPN Pallet (rf.inbound.cwrflocatelpnpallet)

- RF Inbound Container View > Locate LPN button (IbContainerView)

- RF Inbound Putaway (rf.inbound.cwrfputaway)

- RF Outbound Putaway OBLPN (rf.outbound.cwrfputawayoblpn)

- RF Inbound RF Putaway Active (rf.inbound.cwrfputawayactive)

- RF Inbound RF Move LPN (rf.inbound.cwrfmovelpn)

- RF Outbound RF Pack LPN (rf.outbound.cwrfpacklpn)

For the above modules, if the flag is disabled, the system will inherit the lock code from the previous location.

For the above modules, if the flag is enabled and the LPN is moved to another location, the system now:

- Removes the Lock code from the LPN as LPN Lock Code = Location Lock Code.

- Writes IHT 24 / IHT 25 records.

- Inventory gets reduced and increased in the respective ERP bucket (if the location lock code is associated with ERP).

NOTE: The new flag “Remove Inherited Location Lock on Unlocate” applies for

- System Directed Putaway of Pallet and LPN

- Manual Putaway of Pallet and LPN

UPDATED APIs